Back from the Dead

After taking a bit of a hiatus on my 242 I have decided to spend some more time working and driving my 242.

A little back story for the gap.

A couple of years back a ran my oil a little low on my B21FT. I didn't notice it until it was a little too late and my engine was pouched. I pulled the engine in an effort to find what had happened and how did my oil level drop without any leaks or and noticeable smoke while driving. After disassembly I found the cylinder walls were worn and as a result to the low oil but I didn't find the cause. Then it dawned on me, I recall a certain portion of my morning commute that required my coasting down a fairly long hill to a complete stop. A few times I noticed that after I came to a complete stop I smelled a hint of burning oil. I looked at the cylinder head and I found that the valve guide were worn. But how? My only thought was then under a long decel there was a considerable amount of vacuum being generated in the combustion chamber and this vacuum was pulling oil into the combustion chamber and and burning it ever so slightly. Over time the engine must of consumed more and more oil until one day when I flung my car through a turn at highway speeds I saw the oil light come one. By the time I was able to stop it was too late.

So my engine was worn and needed some attention. A friend of my fathers who runs a machine shop suggested to do an aggressive hone to which used to be called a a 10 up oversize. I wanted to use 0.024" oversize pistons but sadly I couldn't locate any at that time for my b21FT so I let him talk me into it. This was a mistake! After all this effort the engine never ran right and before I knew it it was hard to start when cold with low compression in less then 5000 miles. At this point I was pretty discouraged and I really didn't want to spend any more time with the car. I even contemplated selling it.

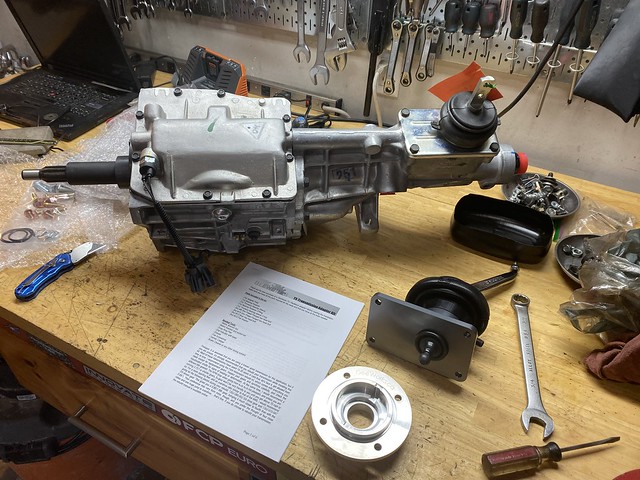

Fast forward to Sept of 2018 and I came across a 91 740 turbo with an m46, hydraulic clutch, and a g80 locker in it. I figured I could pull the B230FT out of it and pop the head off of it and plant my kJet head on it and viola, I could be driving me car again.

After pulling the head off of the b230FT I noticed a large ridge on the top of cylinder #1 so I really didn't feel comfortable resealing that shortblock and installing into my car as I would probably be pulling again in a few months.

At this point I found a new machinist who had his own machine shop and he was willing work with me to refinish my block so I would have a working reliable engine.

We built a usable shortblock that was going to help me get my beloved 242 back on the road.

While the block was being built I began to contemplate what do for EMS. Currently I had a functional working kjet car and after working with the system for a couple of summers I liked the ease and simplicity to keep it running. What I didn't like was the fuel consumption. This thing was a pig at with reserved driving I could hope to achieve 17 mpg.

With my driving style and engine configuration I was averaging 15!

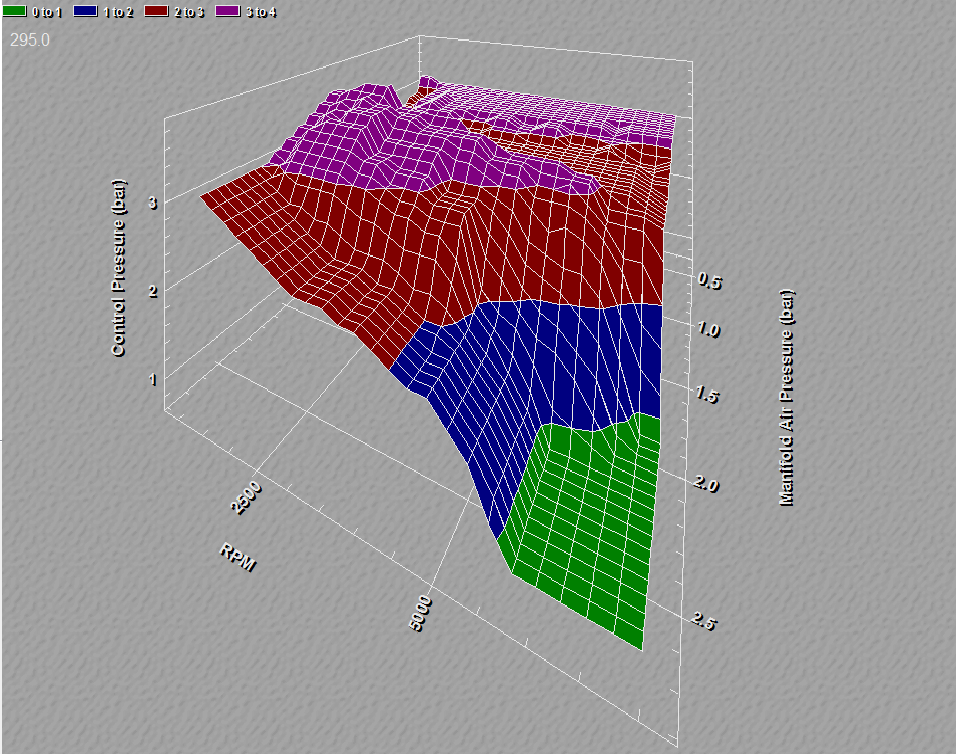

However after doing some more thinking I decided to change the EMS to LH2.4. The swap seemed easy enough and other then the harness I had pretty much everything I needed to get it to work.

So that's the route I went. I wished I had taken some pictures and documented this process but life takes over and sometimes working on the car is all I had time todo.

What I was able to do it to get a working LH2.4 B230FT in my 242 with wasted spark, a hydraulic clutch. The car is drive able and fun again and with some additional changes it could be even better.

So at this point I am reviving my build thread.

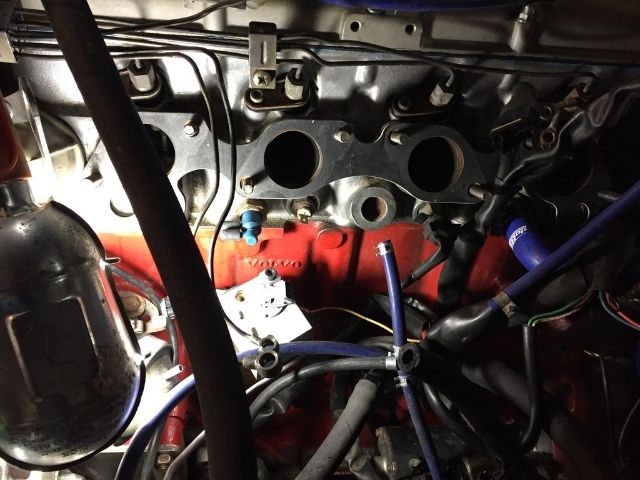

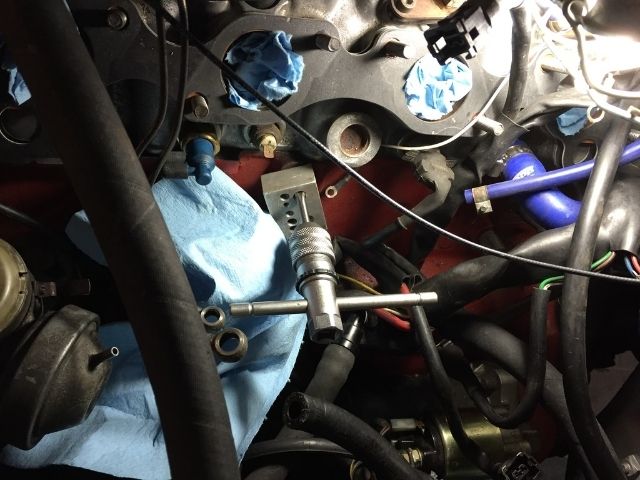

This is as it sits now.

more to come.