Terry1941

New member

- Joined

- Sep 9, 2020

- Location

- Federal Way, Washington

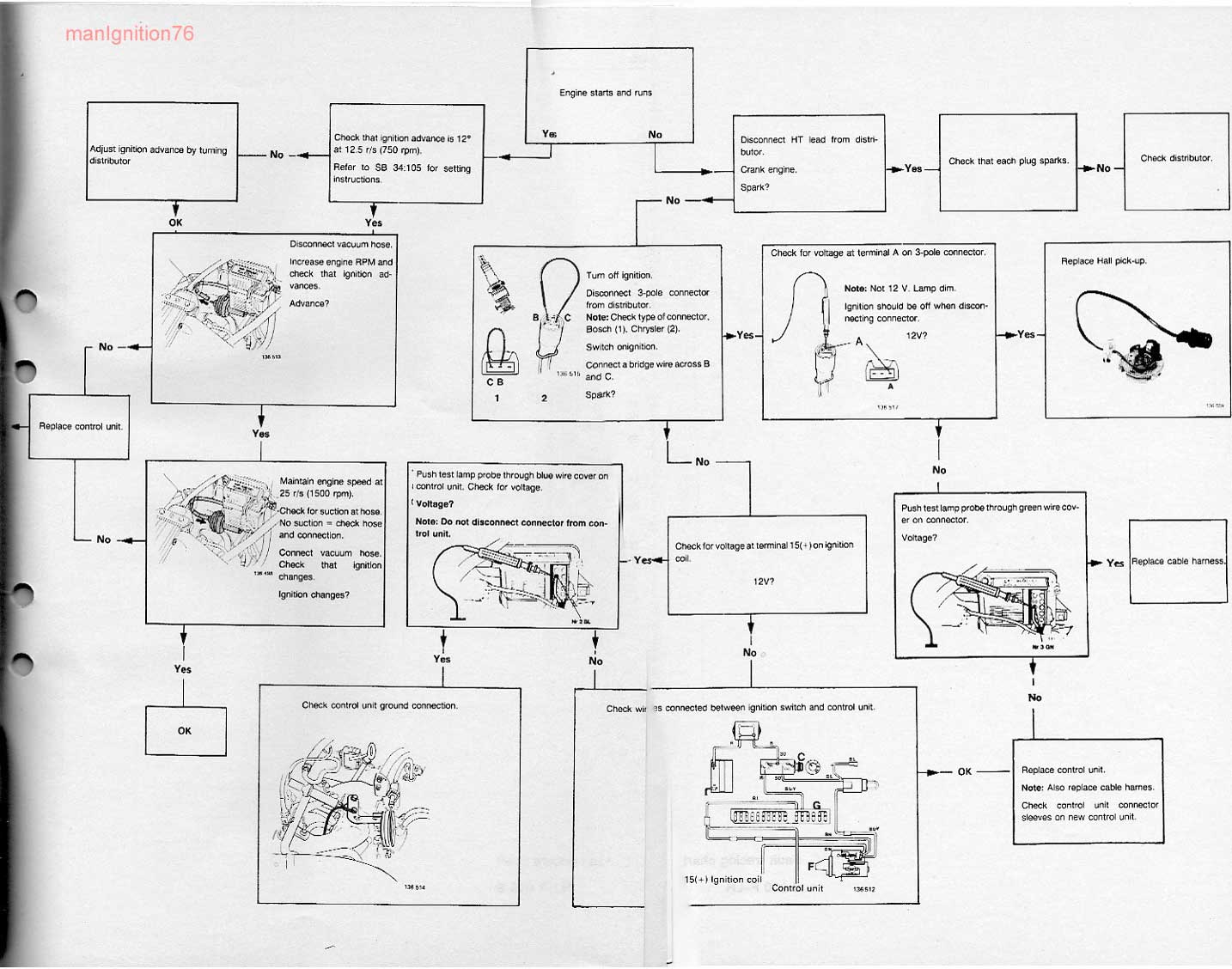

My daughter was driving the Volvo from her friends house in Renton back to Tacoma and while driving about 45 mph heading towards the freeway the engine stalled. She was able to coast into a nearby business parking lot. When I arrived to tow the car back home I noted that the key worked, the lights came on, the engine would turn over, there was gas and oil where it should be. I now have to troubleshoot to see just what might have happened, fix it, and get her back on the road again. Any suggestions on where to start?