TriaxialBulls

New member

- Joined

- Oct 28, 2021

Alright I'm gonna need help from the Bosch ignition experts on this one. I'm at my absolute wit's end with this ****ing car and I'm seriously considering taking it to the junkyard. Please help me avoid having to do that.

Currently trying to chase down a no spark/no start issue on my 1989 (so it has Bosch LH2.4) 245. It was intermittent for a couple weeks but now it won't start at all.

The whole system looked pretty old so I replaced (in order):

-Crank position sensor (the one on top of the bellhousing)

-Cap/wires/plugs/rotor

-Coil

-Power stage (aka the ICM aka the ignition amplifier, it's the little thing behind the driver's side headlight)

None of that made any difference. Still no spark and no start. I removed the EZK box, took the computer out just to see if there was any obvious corrosion or blown components. The thing still looked brand new so I put it back in it's case.

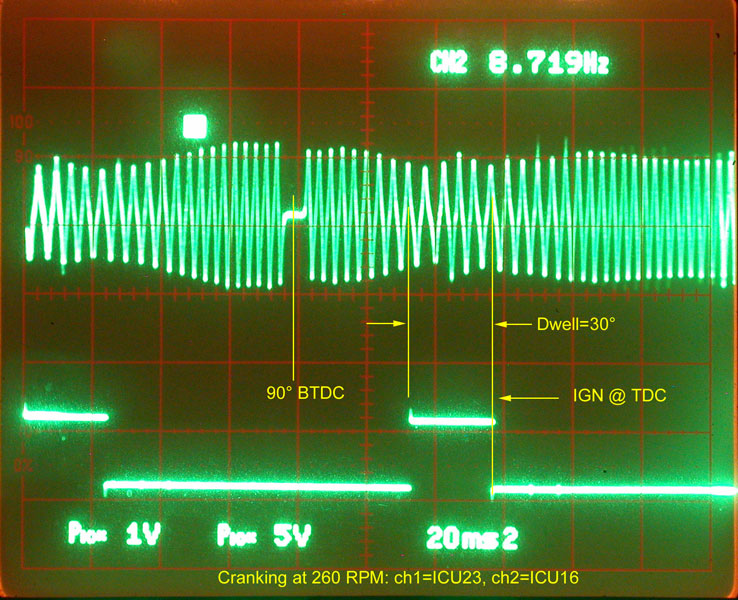

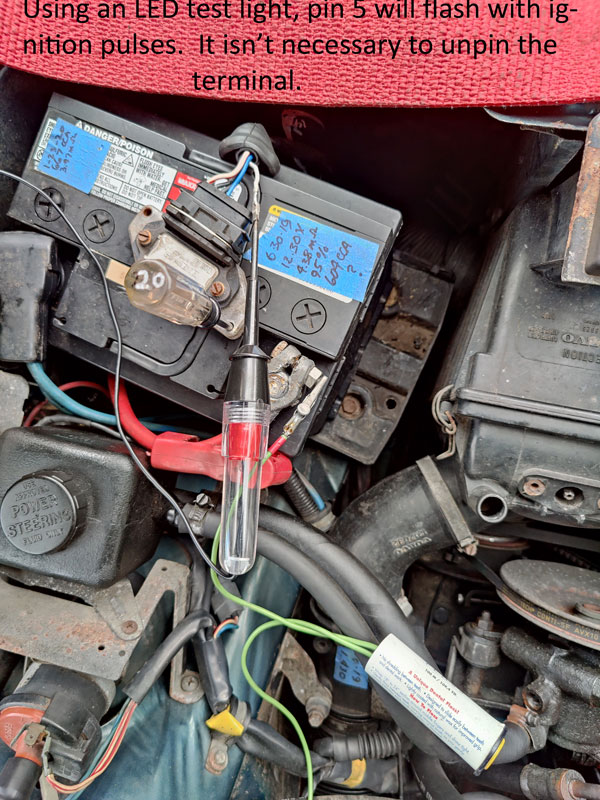

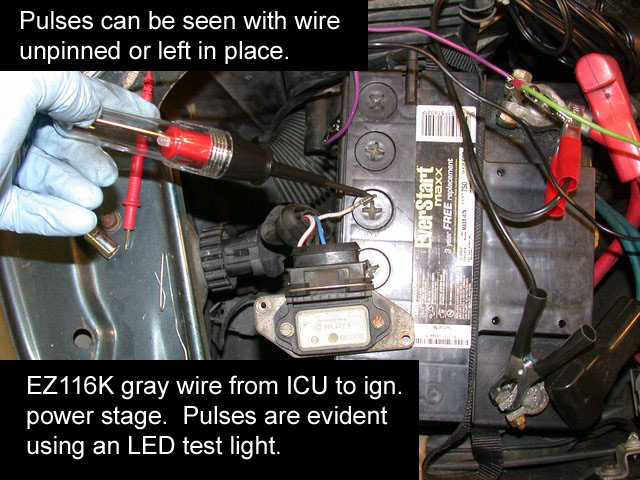

Earlier today I put my meter on pin #5 of the plug that goes to the ICM up by the driver's headlight. This is the pin that should be receiving the AC signal from the EZK (which is receiving it from the crank position sensor) and got nothing. So I know it's either an issue with the brand new CPS, the EZK, or the wiring somewhere between the three components.

I tested the resistance of the CPS and got 170 ohms which is right within spec (150-230 ohms). Next I'd like to try and test to see if the sensor is putting out a signal while the engine is cranking, but I'm not sure how to do that. There are three pins on the connector and I don't know which ones I should be putting my probes on while the engine is cranking.

Can anyone offer any advice or explain to me how I can test the CPS? Any help is greatly appreciated.

Currently trying to chase down a no spark/no start issue on my 1989 (so it has Bosch LH2.4) 245. It was intermittent for a couple weeks but now it won't start at all.

The whole system looked pretty old so I replaced (in order):

-Crank position sensor (the one on top of the bellhousing)

-Cap/wires/plugs/rotor

-Coil

-Power stage (aka the ICM aka the ignition amplifier, it's the little thing behind the driver's side headlight)

None of that made any difference. Still no spark and no start. I removed the EZK box, took the computer out just to see if there was any obvious corrosion or blown components. The thing still looked brand new so I put it back in it's case.

Earlier today I put my meter on pin #5 of the plug that goes to the ICM up by the driver's headlight. This is the pin that should be receiving the AC signal from the EZK (which is receiving it from the crank position sensor) and got nothing. So I know it's either an issue with the brand new CPS, the EZK, or the wiring somewhere between the three components.

I tested the resistance of the CPS and got 170 ohms which is right within spec (150-230 ohms). Next I'd like to try and test to see if the sensor is putting out a signal while the engine is cranking, but I'm not sure how to do that. There are three pins on the connector and I don't know which ones I should be putting my probes on while the engine is cranking.

Can anyone offer any advice or explain to me how I can test the CPS? Any help is greatly appreciated.