Not to mention burning up your brushed DC motor by using Regen.

Oh no, you mentioned a brushed DC motor. Prepare for the

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

Not to mention burning up your brushed DC motor by using Regen.

Oh no, you mentioned a brushed DC motor. Prepare for the

That is a question he should know based on his experience. So he should be able to answer it. It make no sense to ask a question like this if you build evs for a living. The controllers are built and the ev's are moving down the track.

And I m here to help swedebrick the OP and have offered him alot if he chooses to use it . Right now I'm having to defend my advice to him which actually has nothing to do with helping him.

Experts? Motorola isnt? OK.... But Bob theres no need to try to slam the chip many people are using it in EV already.This thread isnt about that chip but your making that your only argument because of your overcite about it. You know no battery power hand tool runs at 30hp and no rc toy uses sensored bldc controllers but RC CARS. Your still chasing your tail because I started off showing controllers much more advanced than reinharts and his budget wont by them either. Its isnt my fault real ev cost real money! If you have to write and ask somebody about the chip then its safe too say you dont much about it.

If you want to ask them about drives ask them about MGMCOMPPRO or APD.... and when you aske them about any of it they will tell you yes it works....

And why would you ask them about that topology when that isnt the one you were shown by me to drive a high current bridge

See this is really quite silly. What you have just posted about the chip mean nothing. Its a logic based ic you know fast acting . I suppose if you really knew about this there would be no heavy debate. He only needs basic motor control and a good regenerative brake the brushed or brushless dc motor provides. Its a great IC and particularly helpful for people not at inverter design and the complexed programming involved. You should be aware that digital logic circuits are very fast. Logic arrays are what you find in missile control systems and one problem with FOC based controllers is there ability to process fast enough for high pole count motors. High pole counts mean more torque. Fast MCUs mean more money and complex programming. You pay for that.... Since my proposal is fairly antiquated and simple it work within his budget and doesn't not require a fancy controller. It bring the price down considerably. This build wont don a 6000 inverter so why even go there if there even a chance to materialize. Why worry about high efficiency when HE said he doesn't care about 19 points of. And still sub 5s aren't too shabby for the money he will spend. There is nothing any simpler or safer about retrofitting a drive train or electronics from a 4 wheel drive toyota to a volvo. It def isn't cheaper.

He did answer it, you didn't. I think he called you on bull**** and you had no logical response that didn't make you out to be a bull****ter. That's just my take on how your responded and continue to respond.

I'll sum it up for you. In a real world design meeting you would get the living **** slapped out of you and would be shown the door if you behaved like you do here. That's why I have already shown you the door here once. Do you have any clue how to carry on a discussion that actually becomes a learning experience for those involved?

Don?t really know that you do it well. Especially when touting on about nine points of efficiency and then throwing air cooled warp 9s in the same post. It?s absolutely beautiful. I can say that you really do have a place that you shine in here. Your deflection skills are absolutely beautiful, something even the best shady used car salesman can?t match.

To the resistor bank. If done the TB way, that means a pile of electric oven burner coils strapped to the roof rack lol.Where is all that regen energy going to go when the batteries can't take it?

To the resistor bank. If done the TB way, that means a pile of electric oven burner coils strapped to the roof rack lol.

Perfect for warming up your frozen gas station burrito on the way into work.

or a heater in the winter for those northern climates

I just zip tied the hose under the dash mostly closed since the heater won't shut off due to bad heater valve.It's a 240, blown heater core and the hoses are looped

That was a joke btw

And why would you ask them about that topology when that isnt the one you were shown by me to drive a high current bridge.

[blah blah blah]

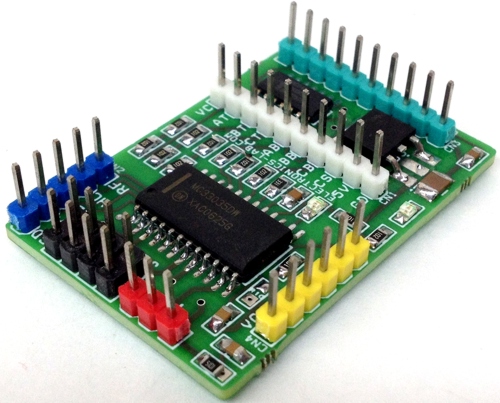

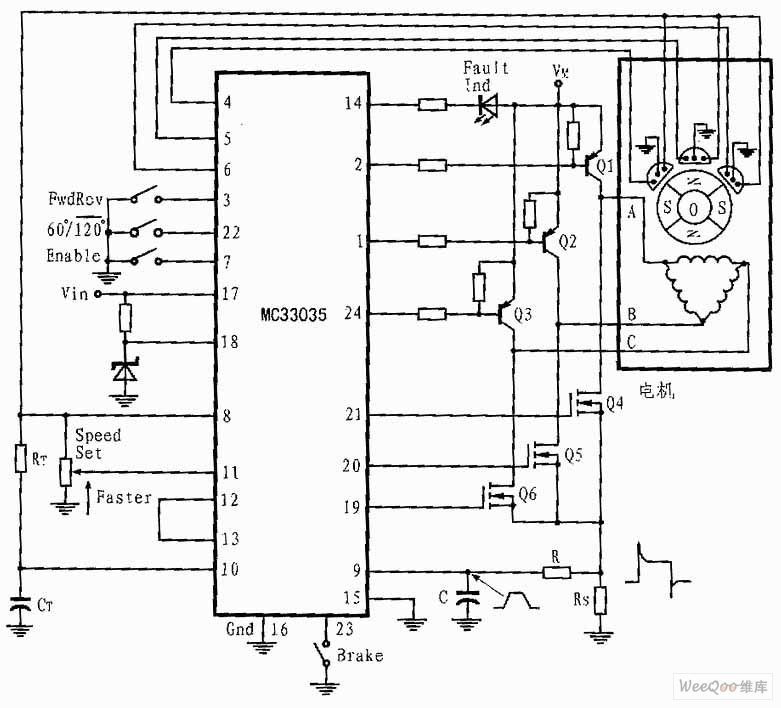

this is a breakout board for the logic IC. Build a bridge with hard switching fet or IGBT (high voltage) and this is the logic that runs it. It times commutation with a hall sensor on the motor shaft. Put the H bridge in a large car audio amplifier chassis and run fan and liquid cooling through the chassis. The inverter is proportionately controlled by drive by wire throttle. Because the fast processing needed for commutation is handled by the logic based ic you can incorporate fairly unsophisticated microcontroller to provide a GUI for controlling the IC's options.

Building a drive really cant be much simpler than using an IC like this to control a dc or 3 phase bridge.

OK, time to put up or shut up. Since you've "been there done it already", let's see the pictures. And since the context of this thread is an EV turbobrick, I want to see pictures of your controller being used with a real automotive traction motor, not another low voltage, small motor, open-loop application. So, got any pictures to back up your claims?One can build a rhobust bridge and fire it with the IC been there done it already...