RR

Member

- Joined

- May 15, 2003

- Location

- Northern CA

Ok, I have done enough searching and youtubing...here's my question...

1970 142 with B20B engine, I have the head off to the machine shop for necessary refurbing, 123 ignition on bench ready to install and cam gear off the car but cam retainer still in place as well as crank gear.

The old lifters are out, new ones coming with D cam; and I want to replace the old cam with the new cam.

I have watched enough videos to know how to do the replacement, but...

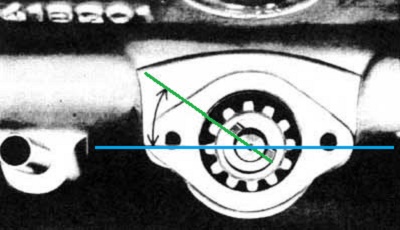

do I need to mark the distributor gear after shaft gears are aligned and #1 top dead center, before pulling the distributor gear out of the engine? I know the dizzy gear needs to come out before I remove the old and slide in the new; but not sure why or if I need to mark the dizzy gear or not. Also, was the gear properly oriented before pulling???

This timing issue still puzzles me...

Thanks in advance, Rick

1970 142 with B20B engine, I have the head off to the machine shop for necessary refurbing, 123 ignition on bench ready to install and cam gear off the car but cam retainer still in place as well as crank gear.

The old lifters are out, new ones coming with D cam; and I want to replace the old cam with the new cam.

I have watched enough videos to know how to do the replacement, but...

do I need to mark the distributor gear after shaft gears are aligned and #1 top dead center, before pulling the distributor gear out of the engine? I know the dizzy gear needs to come out before I remove the old and slide in the new; but not sure why or if I need to mark the dizzy gear or not. Also, was the gear properly oriented before pulling???

This timing issue still puzzles me...

Thanks in advance, Rick