Many people associate ENEM with camshafts and it may not be so con-has been designing and manufacturing camshafts for over 25 years. All combs with an ENEM number is ground on new raw materials, which gives the camshafts ma base circle as original (with a few exceptions where this is not possible). In this way, original shims fit for valve adjustment, hydraulic lifter works as they should and the valve geometry will be correct. The profiles are of course calculated using a computer and software. but for this we have had to develop ourselves, which has given us the opportunity to adapt the calculations in line with new engines and new technologies. No camshaft manufacturer can create optimal camshafts with just one computer and a program, they must be tested to confirm that the data supplied entered into the computer were the right ones. Experience means that you often get close immediately the final result, but when looking for the optimal, it is important to you test and optimize settings yourself, etc. This is something we have consistently done at ENEM because we are also a build complete engines with test bench for testing and development.

An interior image from the test bench and a Rallycross engine. Here different camshafts and settings are tested, injection systems are programmed, etc. A common misconception is that we only work with Opel engines. Of course we drive a lot Opel but it is just as much of other brands. This is partly due to the fact that we, as general agent for MBE Systems in Scandinavia, deliver complete injection systems and also brakes and folds the engines. When it comes to camshafts, we grind Alfa, Audi, BMW, Ford, Peugeot, Volvo, VW, etc. for colleagues. Of course, we also get from them "feed back" that talks about what is going well and less well. By this we mean that an ENEM comb is a quality product that works, moreover usually to one lower price, there are no middlemen because we manufacture ourselves.

Sharpening camshafts is a craft. Of course there are controlled fully automatic machines but you can only find such at

the car manufacturers. The machine is controlled by so-called production masters which in turn was made from the primordial master that we milled out after a data list. One for exhaust and one for intake. The ridge angle is fixed between the masts and the entire master package is rotated with fixed indexes between the cylinders, which guarantees precise division.

Page 2

CAMAXAS

Our stationary test bench can handle to brake just over 600 hp - which has happened several times, Porsche dual-turbo, Viper GTR, K?nigsaegg etc. The torque we can handle is just over 1100 Nm at about 2500 laps - which was also tested. An interior image from the test bench and a Rallycross engine. Here different camshafts and settings are tested, injection systems are programmed, etc. A common misconception is that we only work with Opel engines. Of course we drive a lot Opel but it is just as much of other brands. This is partly due to the fact that we, as general agent for MBE Systems in Scandinavia, deliver complete injection systems and also brakes and folds the engines. When it comes to camshafts, we grind Alfa, Audi, BMW, Ford, Peugeot, Volvo, VW, etc. for colleagues. Of course, we also get from them "feed back" that talks about what is going well and less well. By this we mean that an ENEM comb is a quality product that works, moreover usually to one lower price, there are no middlemen because we manufacture ourselves.

Page 3

CAMSHAFT - MOTORNSNERVE!

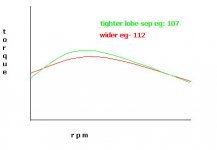

Sounds dramatic but the fact remains, it is camshaft times and lift height that decide the character of the engine. Long comb times improve high-speed properties but deteriorates at low revs, shorten the satta. Choosing the right comb is always one

compromise, preferably one wants do not abandon the low speed the engine but the engine gets happy to give more effect on higher turn...

Every cam designer's ambi-is, of course, to achieve get the best of each but it must always be a compromiss, the comb that gives a lot of peak power is coming always to lose some of the tendrils and vice versa.

Opel 1.6-2.4 X1 288/109 / 11.7 / 2.2

This is how we specify the camshafts' designation and data, and this is what the codes mean:

? X1 is a coordinate that indicates where in our archive we are shall find the master of the comb. So it has nothing to do with what kind of comb it is or how sharp.

? 288 is the duration in crankshaft degrees, the measure of how many degrees the crankshaft rotates from the time the valve opens until it closes. Longer duration usually means a sharper comb, short duration a kinder with a certain reservation: Combs for 4-valve stops are due to it larger valve area with two intake and two exhaust valves and lighter mechanism gene- really sharper with same duration than corresponding comb intended for a 2-valve stop.

? 109 is the ridge angle , the number of degrees between the center line of the cams measured on the camshaft. A smaller ridge angle means - among other things - that the overlap is longer, ie both valves are at the same time open for more degrees.

It is often said that a sharp comb always has a small ridge angle and most often it is true but again there are exceptions. Depending on the conditions in the crank the mechanism (stake lengths / stroke) and intake the length of the pipes gives many engines more power on high revs with a larger ridge angle. Overcharged engines provide almost without exception more effect with large ridge angle.

? 11.7 is the valve lift, given at 0-valve play. More lift gives, if the top flows more on high valve lifts, more effect. You usually do normally try to make the combs with as much lift as it is possible without stress one on the valve mechanism gets too high. When it comes to sports combs, we take also consideration of how much lift one can have without having to change springs etc.

? 2.2 is the opening of the intake valve at the top dead center, when the piston is in the top position. This is the setting measure for the comb, as we are found that it works best. You measure best by fitting an indicator clock on one suction valve, pull the engine clockwise from the front as it then goes and reads how much the valve opened on the ?D. When measuring, the valve clearance must be set correctly if it is a cam for mechanical valve lifters, if it is a hydraulic you must measure at 0-game. Can be difficult with a new hydraulic lifter, it will be the mute only when you run the engine for a few minutes.

If you have fitted a sharper cam, remember to always check the clearance between valves and pistons. When the cam is set correctly, you should have at least 2.0 mm clearance. If there is an adjustment, turn it down so that the valves open 2.0 mm, (one cylinder at a time), remove the pins and carefully pull the engine around in the direction of rotation. you know immediately if it receives, or if valve springs bottom, etc. If so, you must mill deeper valve outlets in the pistons, replace valve springs or whatever it takes to get it around. In our list of camshafts, we have tried to specify a suitable speed range, graded from 1-6. If you need a standard comb, then 1 applies. If you choose 6, we have assumed that the engine will be tande run at high speeds under competition conditions, and the engine is ready-set for this, you have high compression, double carburetor or injection, suitable exhaust system etc. Our experience is to recommend one ?for please ?comb, it turns out in most cases that the car goes faster - or is better that drive - with a wider effektregister, one should not be too presumptuous and add to the top. An engine intended to run over 4000 laps requires a good gearbox and an experienced driver.