hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

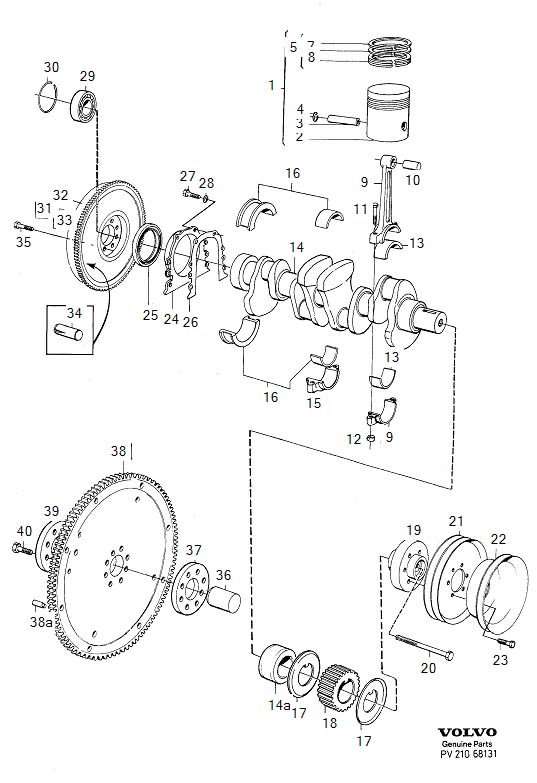

Rod journal diameter and width is not the same on 6 and 8 bolt cranks. 6 bolt crank rod journals are slightly larger (54.102 mm vs. 54.0 mm) and slightly wider (32.05 mm vs. 30.05 mm) than 8 bolt crank rod journals. The main journals are the same.