Removed my stock differential on my 87 244 DL to install a racingdiffs LSD conversion kit and I got stumped by the cross pin. Right now, I have the differential out and the ring gear still attached and it seems like I just need to knock out a small locking pin that goes through the cross pin so I tried hitting it with an alan key and a hammer. I started with the ring gear on top and hitting it and got a little bit of movement but couldn't get it more than still a couple of millimeters below flush on the exit hole so I decided to go at it the other way and I got a little bit of movement back but still not much. I tried to look up anything I could think of about this but I couldn't find much about this particular issue. I also may need to remove the ring gear to get the conversion kit in and don't know how to remove the cover that's over top of the bolts without mangling it. any input would be greatly appreciated.

-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

240 diff disassembly

- Thread starter tog244

- Start date

dl242gt

The world of the smiling Dogo

- Joined

- Jun 21, 2002

- Location

- S NJ, a suburb of Phila.

To hammer out the pin you need a good punch. That will let you hit it a lot harder than an allen wrench will. Not sure what cover is over the ring gear bolts. Are you referring to the tone ring for the speedo? If I recall correctly that is a press fit onto the diff. There is also an oil slinger plate on the side of the diff. It is held on with the bearing on that side. You have to pull the bearing to get the slinger cover plate off. Don't lose the shims for the bearing.

I did some research on jeep forums for the dana 30 and I think I need to buy or make a better punch, I think I have some 1/8 in steel rod that will work well. for the ring gear, there's a plate that covers the non-toothed side (the left side of it when looking from the rear of the car) it might be the oil slinger that you mentioned. What's the process for pulling the bearing? Do I need a bearing puller or is it simpler than that? *also I might not even need to remove the ring gear to slide the kit in, I can't tell yet.

hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

Volvo introduced the crown wheel screw lock plate in early '73 to deal with the bolts coming loose.

Before that there was a TSB to install lock washers under the bolts and Loctite on Anti-Spin diffs.

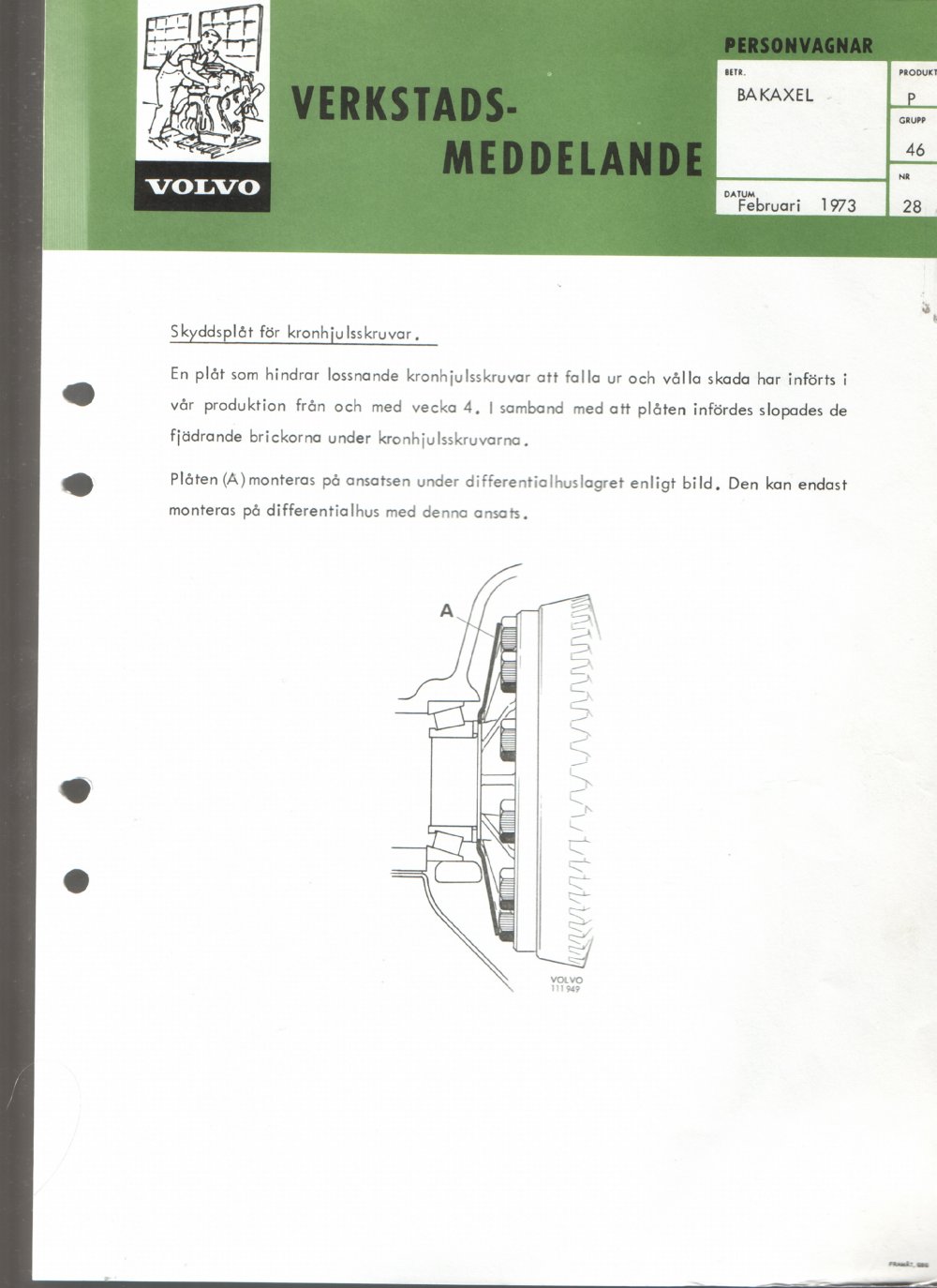

Protective plate for crown wheel screws

A plate that prevents loosening crown wheel screws from falling out and causing damage has been introduced in every production from week 4. In connection with the plate, the resilient washers under the crown wheel screws were removed.

The plate (A) is mounted on the shoulder under the differential housing bearing as shown. It can only be mounted on differential housings with this shoulder.

Before that there was a TSB to install lock washers under the bolts and Loctite on Anti-Spin diffs.

Locking of crown wheel screws.

To get a more secure locking of the crown wheel screws, we have inserted a resilient washer under the screw heads. On gears with differential brake (Anti-Spin), we have also introduced locking with locking fluid on both the crown wheel and the crown wheel screws.

The washers are introduced in every production from and including week 33 locking fluid from and including week 39 (some gears with differential brake require lock washers).

The washer, part number 942336-9, should always be fitted when renovating previous rear axles. Ten washers are required for each gear.

On gears with differential brakes, the grooves of the crown wheel screws and the abutment surfaces of the crown wheel against the differential housing are also provided with locking fluid type Loctite RC (retaining compound). NOTE! First clean the surfaces thoroughly with trichlorethylene or equivalent.

Volvo introduced the crown wheel screw lock plate in early '73 to deal with the bolts coming loose.

Holy cow, I never would have guessed that!

I've always been a red loctite and proper torque kind of guy.

I might just loctite and torque them down and hope for the best in the case that I need to take off the ring gear and can't get the lock plate off without cutting it. That's super interesting though, I couldn't find a single thing about it anywhere else on the internet.

hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

I've always been a red loctite and proper torque kind of guy.

Same here.

Obviously Volvo had a problem with the bolts coming loose or they wouldn't have made the lock plate. Hopefully Loctite has improved their formula since 1973.

dl242gt

The world of the smiling Dogo

- Joined

- Jun 21, 2002

- Location

- S NJ, a suburb of Phila.

Thank you for the update and info on the punches. Hope to hear from you when you have the traction upgrade done.