maxman142001

I like turtles

- Joined

- Jun 2, 2003

- Location

- Phoenix, AZ

This car is gonna be so awesome when its done, I cant wait! Like what you did with the rear bumper/butt cheak area too..so clean

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

I finally have my '91 244 daily driver back in optimal condition, replaced the broken head pipe after work today, among a few other things. I need to start burying myself in the 242 again. Not much in the way of progress, although my vanity plates arrived. Gotta love Vermont, you can still get real words!

Love them plates. YGPM sir.

Love them plates. YGPM sir.

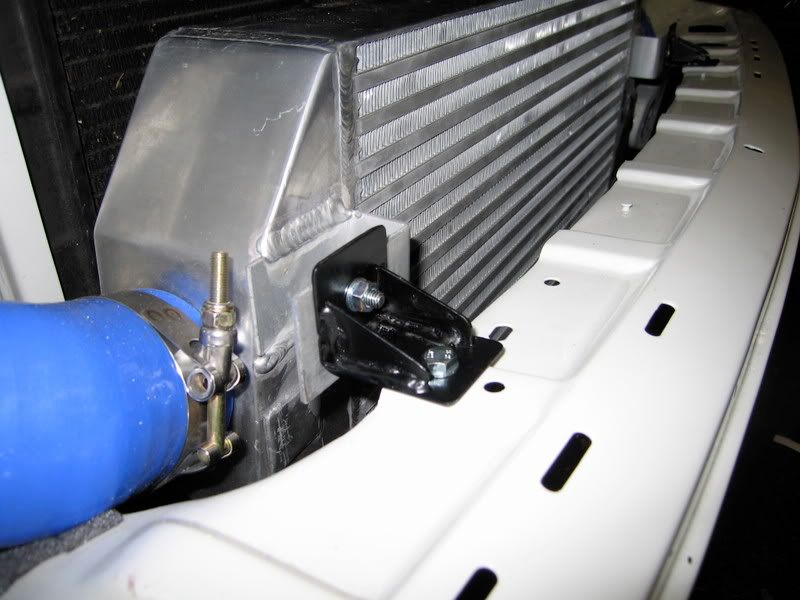

lol. 99.9% of "custom" intercooler mounting brackets i see on here are bailing wire or wire tape with some drywall screws, your mount looks to be the shiz-nito-snip-snap-snap

good work man

Very nice! I'll be watching this closely. What are you doing for the interior?

Also, are you keeping the wastegate dump open like that?

. My father builds street rods and is the expert in making seat adaptor brackets. So I'll come up with something cool.

. My father builds street rods and is the expert in making seat adaptor brackets. So I'll come up with something cool.Yep, leaving the WG dump open for now. If it's too raucous/fumey I can reroute it, or plumb it into the down pipe.

Lemme know if you want a custom dashboard made to your specs buddy. I gots me a nice 242 to mold it from in the backyard with half of the dashboard already ripped out of it.For the interior I have a mostly complete 242 black interior, including an uncracked dash, nice carpeting and most of the plastic bits. I actually got it for free off Craigslist a few years ago. It was one of those "an old tenant left a bunch of junk Volvo parts in my basement - come clean them out" type deals.

including an uncracked dash

nice! i love the vanity plates. you may not have made a **** ton of progress recently but at least you made some, now finish it!

nice! i love the vanity plates. you may not have made a **** ton of progress recently but at least you made some, now finish it!