ogamer777

Loading...

- Joined

- May 22, 2016

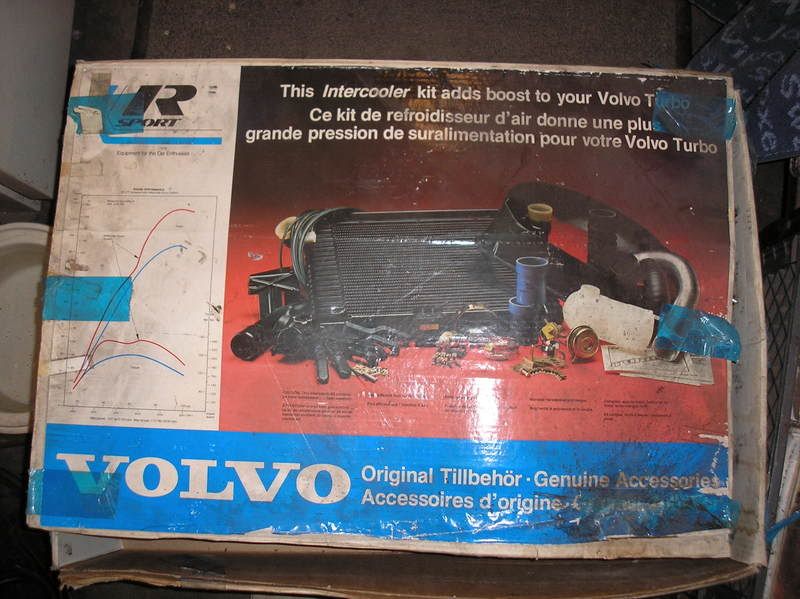

I recently purchased a replacement volvo after bending the rear axle on my 242. I ended up purchasing an 82 244 turbo. Nice car nearly fully loaded (even came with the super rare rear sun shade from the factory! among other things) I am looking to locate and install a full intercooler system.

I would prefer a factory volvo 240 intercooler setup to maintain reliability and keep cost down without sacrificing reliability.

I did a quick search and saw that there was a couple of different thoughts about what setup to use as well as BOV myths.

I do want to install a blow off valve eventually but its not important at the moment. And really neither is the intercooler but i would like to plan ahead and at least locate the parts needed to do the install completely.

So i would like to know, what parts are needed to install a factory 240 intercooler system, where i might find those parts, and if any parts would be different due to my eventual plan to install a BOV as close as i can to the throttle body

Thanks

Ethan

I would prefer a factory volvo 240 intercooler setup to maintain reliability and keep cost down without sacrificing reliability.

I did a quick search and saw that there was a couple of different thoughts about what setup to use as well as BOV myths.

I do want to install a blow off valve eventually but its not important at the moment. And really neither is the intercooler but i would like to plan ahead and at least locate the parts needed to do the install completely.

So i would like to know, what parts are needed to install a factory 240 intercooler system, where i might find those parts, and if any parts would be different due to my eventual plan to install a BOV as close as i can to the throttle body

Thanks

Ethan