mrak

Beefsma by Design

- Joined

- Feb 14, 2016

- Location

- Soldotna, AK

So recently I picked up a 93 245 that cranks but won't start. The guy who had it last said it was running, then started to stumble and fail. He replaced the AMM with what looks like a JY unit. He was a Ford car guy who didn't know anything about Volvo's. The only other information I got from him was that he had plugged and unplugged the AMM while the car was running, but I don't know if that causes any failures.

Since then I have.

-Changed the ECT Sensor

-Replaced the Spark Plugs

-Replaced the CPS

-Replaced all fuses in fusebox and brushed down the holders.

-Verified the cam dowel still exists and the cam turns during crank

-Verified spark both physically and with a timing light.

-Checked for codes - 1-1-1 from ICU and ECU

-Checked the CPS, injectors, and IAV with the obd unit.

-Checked the injectors with a noid light, they flash

-Checked fuel pressure at the rail

-Checked for fuel from the fpr

-Cleaned the grounds at the rail.

-Checked compression

-Tried to start the car with starting fluid.

-Checked for blockage in the airbox.

The car cranks over beautifully, but doesn't start. Sometimes when you turn the key off, it will stumble and diesel along for a second or two. Seems to do this more when using starting fluid. Checking the new plugs, they show no carbon/signs of ignition at all, and seem to have quite a bit of fuel on them. The oil also smells like fuel. It behaves the same with the AMM plugged in or unplugged. It also has a relay by the battery (I believe the AC relay) that appears to have melted partially at some point.

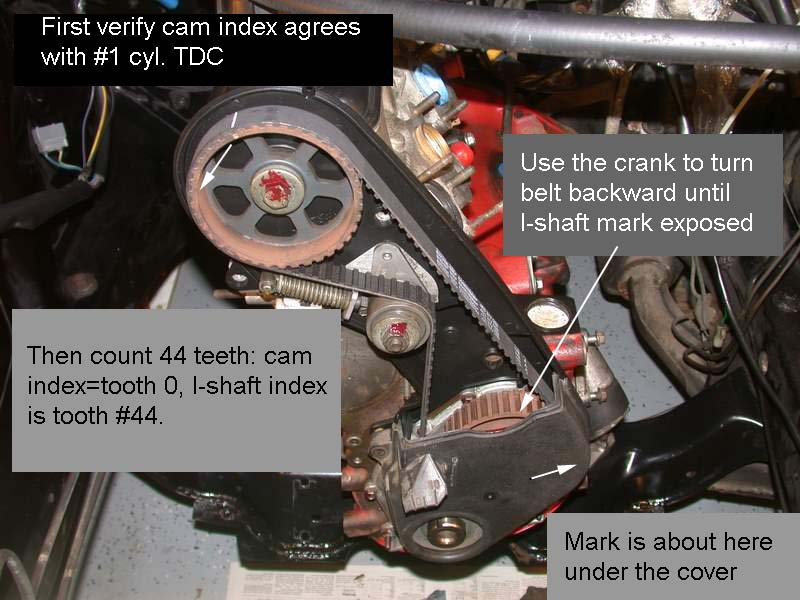

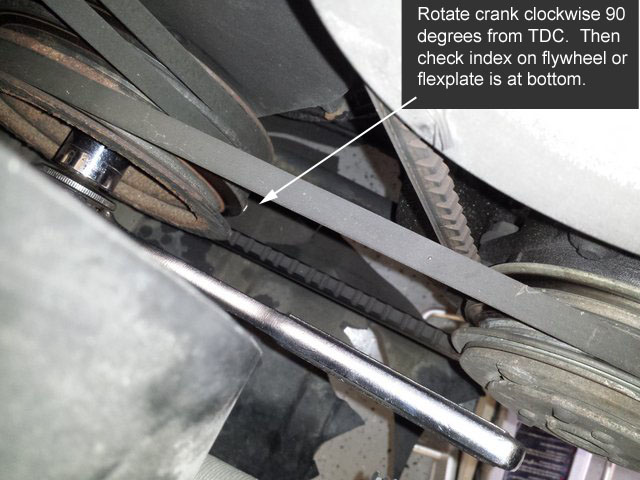

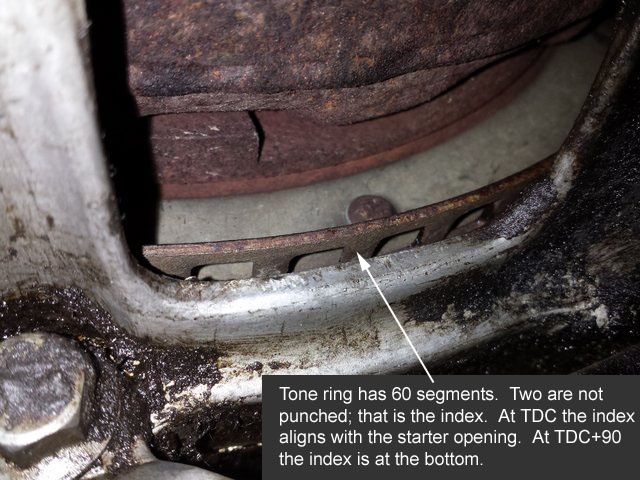

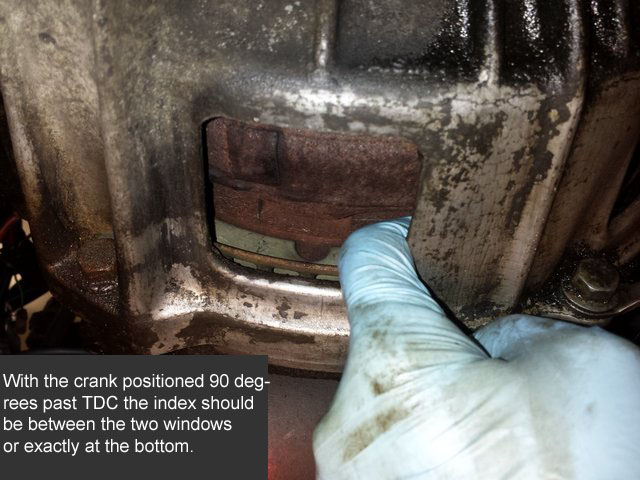

I'm wondering where to go next. I know I need to physically verify timing. I should double check the new ECT resistance. I don't know what would be causing the flooding though, seeing as spark appears to be present.

Would a failing powerstage cause this? Spark plug wires possibly not clicking onto the plug heads? A failed ICU or ECU that still throws 1-1-1 codes but is dumping fuel or erratic timing? Can a bad AMM cause a no-start condition? Would a stuck injector still tick during the OBD diagnostic? Would a flywheel installed by a previous owner in the incorrect position cause this?

I have a 2.4 turbo ECU and EZK box on hand for the future, but I've been hesitant to throw them in the car to troubleshoot. I'd appreciate any suggestions with where to go next.

Since then I have.

-Changed the ECT Sensor

-Replaced the Spark Plugs

-Replaced the CPS

-Replaced all fuses in fusebox and brushed down the holders.

-Verified the cam dowel still exists and the cam turns during crank

-Verified spark both physically and with a timing light.

-Checked for codes - 1-1-1 from ICU and ECU

-Checked the CPS, injectors, and IAV with the obd unit.

-Checked the injectors with a noid light, they flash

-Checked fuel pressure at the rail

-Checked for fuel from the fpr

-Cleaned the grounds at the rail.

-Checked compression

-Tried to start the car with starting fluid.

-Checked for blockage in the airbox.

The car cranks over beautifully, but doesn't start. Sometimes when you turn the key off, it will stumble and diesel along for a second or two. Seems to do this more when using starting fluid. Checking the new plugs, they show no carbon/signs of ignition at all, and seem to have quite a bit of fuel on them. The oil also smells like fuel. It behaves the same with the AMM plugged in or unplugged. It also has a relay by the battery (I believe the AC relay) that appears to have melted partially at some point.

I'm wondering where to go next. I know I need to physically verify timing. I should double check the new ECT resistance. I don't know what would be causing the flooding though, seeing as spark appears to be present.

Would a failing powerstage cause this? Spark plug wires possibly not clicking onto the plug heads? A failed ICU or ECU that still throws 1-1-1 codes but is dumping fuel or erratic timing? Can a bad AMM cause a no-start condition? Would a stuck injector still tick during the OBD diagnostic? Would a flywheel installed by a previous owner in the incorrect position cause this?

I have a 2.4 turbo ECU and EZK box on hand for the future, but I've been hesitant to throw them in the car to troubleshoot. I'd appreciate any suggestions with where to go next.