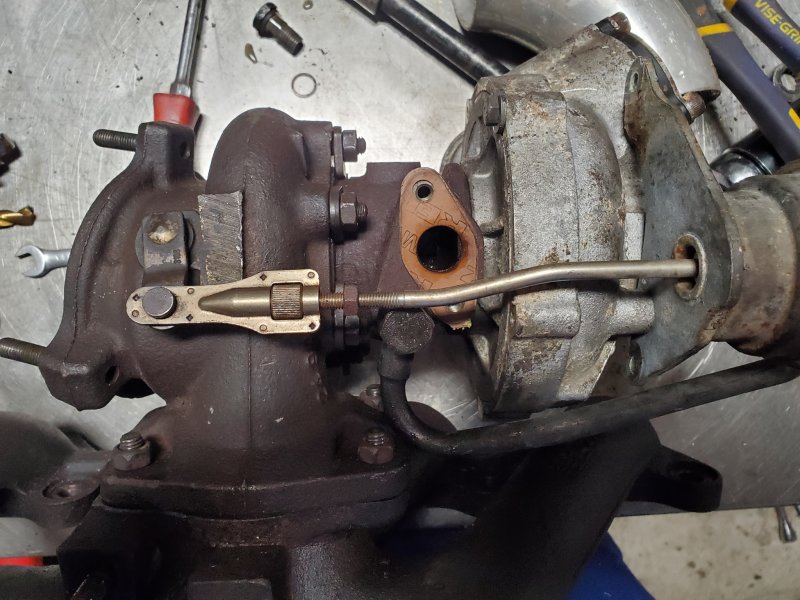

modified the manifold and turbine housing for this part

also did a little opening of the collector area (didn't full on match the k24, but it necks down fairly fast anyway so it'll be fine), nothing special or big so no pics there.

clocked by eyeball (and it looks good on the car too, so I'm gonna leave the positioning and make any needed minor adjustments with the chra, but it looks about perfect too)

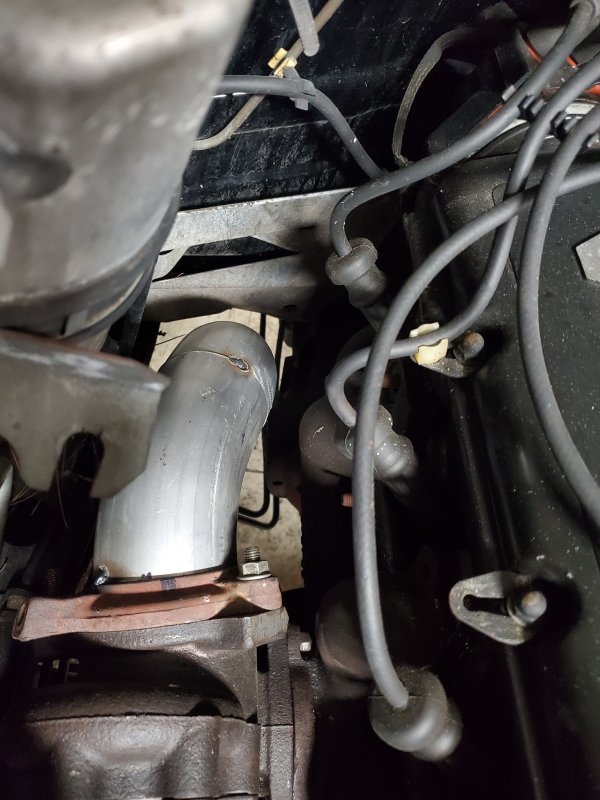

bolted up briefly to check things

discovered the lower coolant fitting is the same size as the 13c coolant lines, this will make things a bit easier to connect the water lines (Although that top one is special, I think I can make it work), also laid out how the gate is going to attach up

cut up another volvo part for sacrificial alu blocks for a second attachment point on the gate bracket.

haters will say that wasn't a volvo part...

not pictured, oil feed is off, oil cooler is floating loose. today's gonna be a short day at work, so I'm gonna probably wrap it up in the shop, try and get the GTO test driven to make sure it's as good as I can get it (friggin stock ecus, been manipulating like 3 numbers to get a nice idle to reverse to drive to neutral to drive to reverse to drive to... transition without setting the idle so high that the car drives off on it's own or tries to drive through the brakes), might cut the grass this morning and then start working on the car again. I'm waiting on a fair amount of little fitting bits and bobs for the turbo install. things seem to be going well though, hopefully this weekend I can get the exhaust wrapped up, all of the fuel system wiring done, intercooler mounted, and be left with some relatively benign stuff coming out of sunday (maybe just bolting the turbo up, that sort of thing) so I have time to get other things sorted out (alignment, charge piping, maybe window tint..ooo.. all of those places are within a block or two from each other).

on a side note-is there anything special about headliner material?