My Holset experiences:

HE351CW - 2.0 16v 4 cyl and 1.8 short stroke 16v 4 cyl - ~3psi @ 3k, ~12psi @ 4k, ~18psi gate pressure at 5k and beyond - loved it, love it, would trade again.

HX40M - 8.3 C series cummins, spools under 1k and keeps spooled to where the over-sized prop stops it with insufficient injector pump - worst ex manifold in the history of the world - log with full sharp 90s inside. Ouch

HY55V - garage floor VGT on RB30DET or B6304 or similar will be interesting, but I'm not sure it'll fit in the front of the car

HUGE. May have to use it for wall art (was $100nz) or rebuild it and play with it for giggles - needs about 1k into it, but it's like a 4k turbo new, so... not terrible.

General:

If you want a lot of power, you're going to have to compromise somewhere, and bottom end torque is where that is, but IMO it's not so bad:

If you're driving slow then you rev to 2k and shift, maybe 3k and shift, the more you rev it the more urgent it feels, the later you shift the faster you go

If you're going fast then you won't see low RPM points in your curve, you'll be shift to shift above 5000 at all times with any reasonable 16v set up and gear set

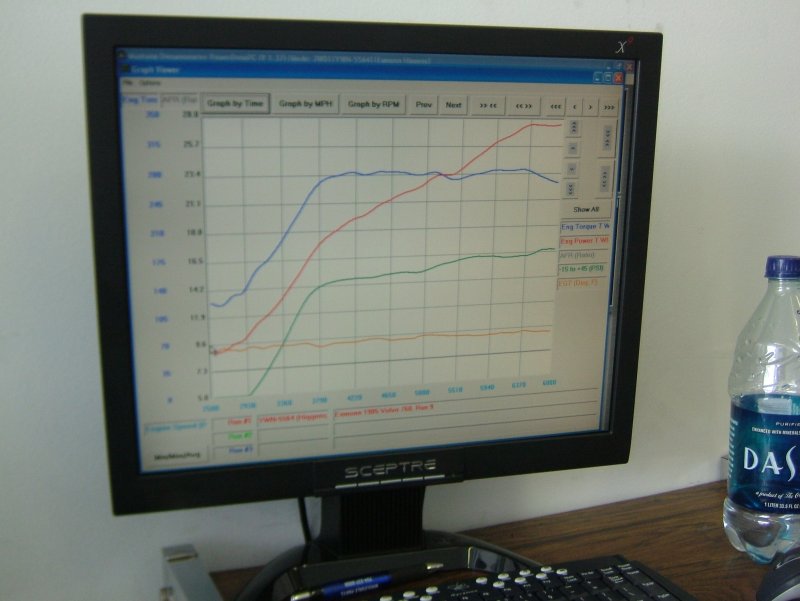

With my HE351CW I welded a steel bung into the 20mm ish wastegate hole and used an external 44mm. With that 44mm wastegate held wide open I made 3.5psi by 7000 RPM on the 2.0 4cyl 16v engine, ie, nicely built ram horn design, using inertia to best effect. In contrast to others in this thread I would describe the spool as gentle - however it's worth noting that at 12psi you're accelerating through the rev range pretty quickly so the ability to make 18psi comes soon after and that acceleration in lower gears makes it seem to come on suddenly, but in reality it's not if you plot it RPM vs pressure. In a higher gear you'd see it coming on very smoothly as strong accel in a high gear is not super rapid.

HUGE. May have to use it for wall art (was $100nz) or rebuild it and play with it for giggles - needs about 1k into it, but it's like a 4k turbo new, so... not terrible.

HUGE. May have to use it for wall art (was $100nz) or rebuild it and play with it for giggles - needs about 1k into it, but it's like a 4k turbo new, so... not terrible.