Nice little update there Aris!

Curious what you end up finding on the fuel system fiasco once you get all that resolved as well.

Now that you mentioned it .. a word of advice for anyone using braided AN hoses for fuel delivery system:

PLEASE DO NOT USE THIS SHIT FOR FUEL DELIVERY !! YOU WILL WASTE YOUR MONEY .. ASK ME HOW I KNOW.

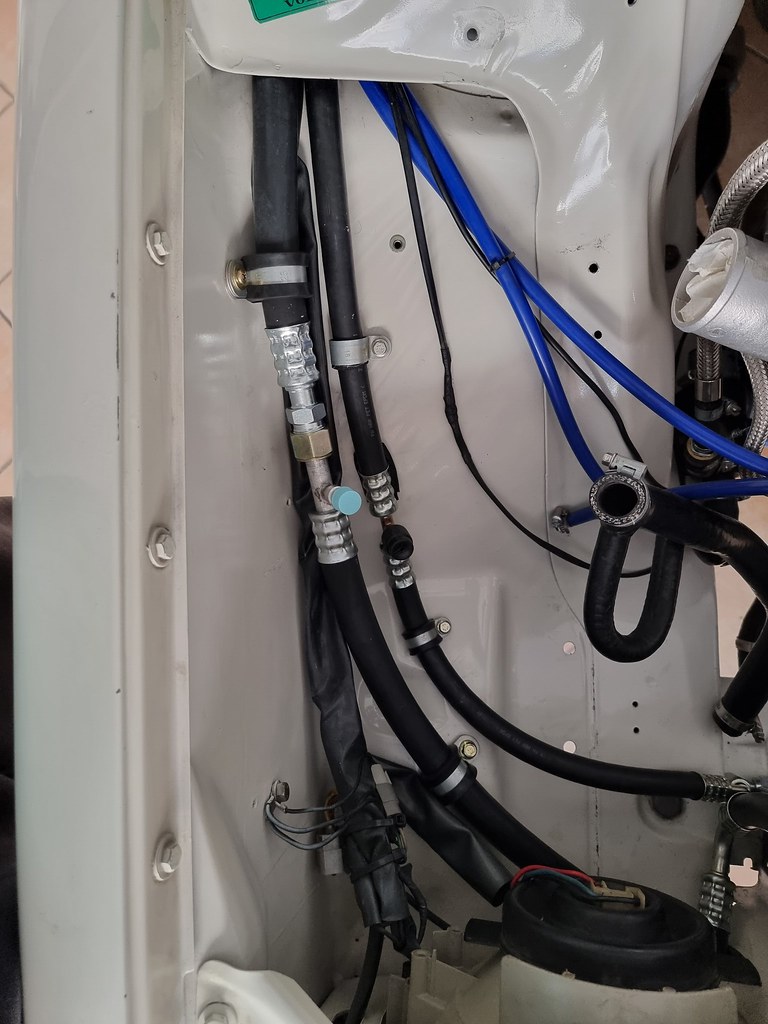

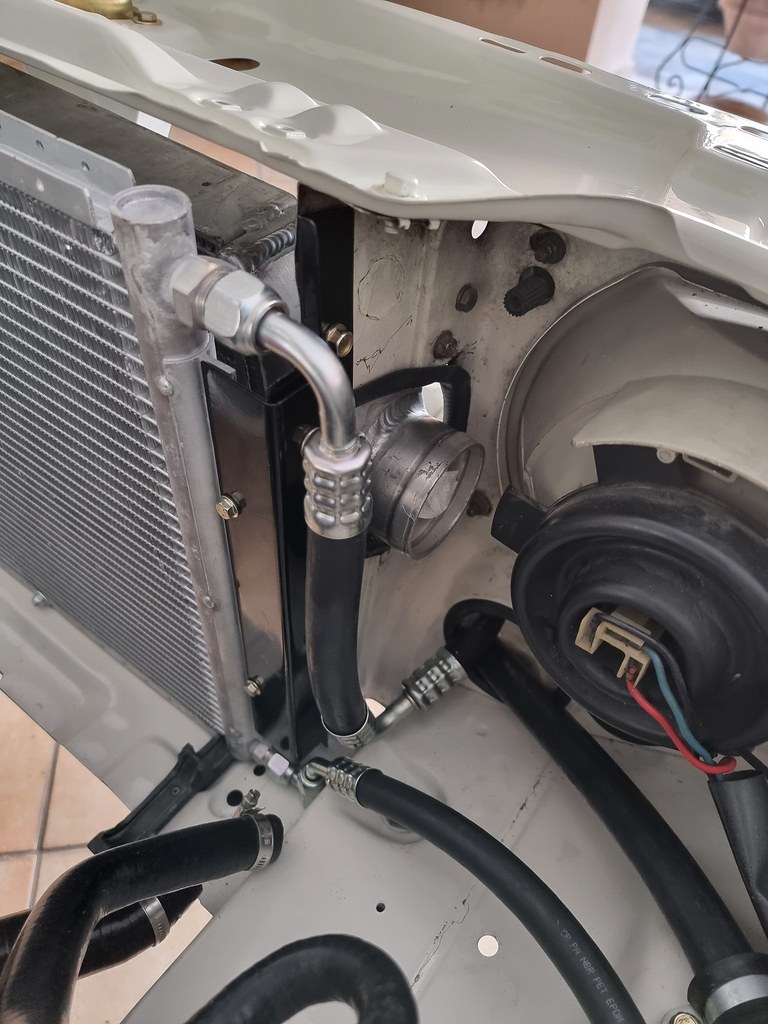

So .. long story short, as you may have seen in the past, Aeroflow braided AN hoses #8 for engine feed and #6 for return to the tank were installed. These lines have been on the car for 5-6 years, while the last 3 years they were drained from fuel due to the rebuild of the engine.

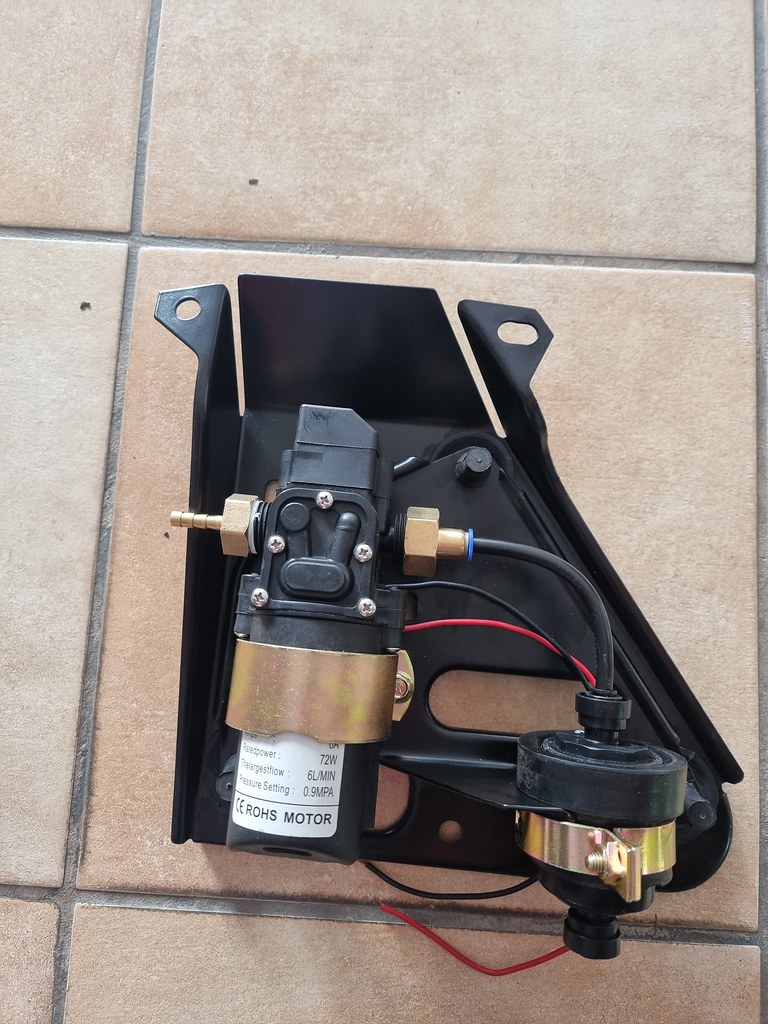

The last week after assembling almost everything on the car, it was decided to pour some 100 RON fuel in the tank and turn on the pump to prime the fuel system before turning the key, to check for any leaks.

Surprisingly, the fuel never made it past the 3 bar FPR because 2 out of 4 meters of the line were literally turned into a kitchen strainer. Fuel was squirting everywhere, flooding the garage. Such expensive lines were useless! Of course the return line when pressure tested was leaking like crazy as well. How do the stock fuel lines last for 50 years and these got wasted so soon ??

After contacting the seller and many others, it was found out that the hoses life count starts when they first get wet with fuel, and stops anywhere between 2 to 6 years no matter if they are being used or are full of fuel or are drained. Of course these can not be used with ethanol or any other "difficult" fuel.

The only thing that made the situation a bit better was that the lines kind of "vaporized"/cracked internally and did not produce any small pieces to block the filter-fuel rail-injectors etc.

So now PTFE lines and new hose ends (since they are not compatible to AN fittings) from NUKE are ordered.

Damn .. always something before the "big" moment !

Fingers crossed they will last a bit longer .. as everybody advertises ...