Parts are starting to arrive, so I need to finish up my engine bay mocking and get the block dropped off down the machine shop.

Haven't been able to do much on the car for the last couple of weeks due to other circumstances but I have 2 weeks holiday coming up soon so am focusing towards getting everything done in the holiday.

Today I fitted a Standard V6 Roll bar to see if it would give the clearance, looks like we have a winner!!!

It was then time to look at the engine bay wiring, I will be using an OMEX ecu system for engine control so will run a completly separate loom for that, and splice where needed into the volvo harness inside the car, but there are still some wires that need to be kept from the old B230ET wiring loom pictured below.

I removed everything to do with the motronic system, leaving just the connector thats on the passenger side bulkhead, which carries the Starter motor solenoid Signal, the Alternator signal, the Oil Pressure switch and the Coolant Temp Gauge wiring.

This is what was left and will look nice and factory when cleaned and tidyed on final engine fitment.

I will probably have to change the plug for coolant temp gauge unless I can figure out somewhere to mount the original gauge's sender.

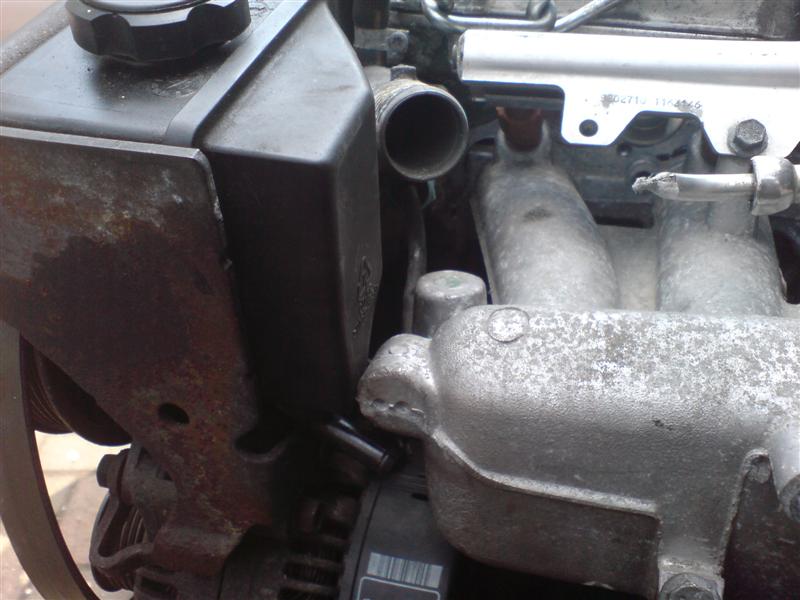

Next I turned my attention to the ME7 inlet manifold, thanks to the casting pictured below the manifold is shifted right about 1cm.

Out with the hacksaw and voila

Now the manifold fouls on the Powersteering plastic return line, so i'm thinking off cutting off the pipe and JBwelding a fitting of somekind directly into the bottom of the plastic tank, which will then allow the manifold to bolt up up without any problems.

Now i'm currently trying to fathom out how to mount the 960 Throttle body to the ME7 manifold. I know i'll have to make a adaptor plate of somekind, but the real fun seems to be getting the throttle spool to open the TB correctly.

I'll put some pics up when i've figured it out.