-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 240GLE

- Thread starter SirNemesis

- Start date

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

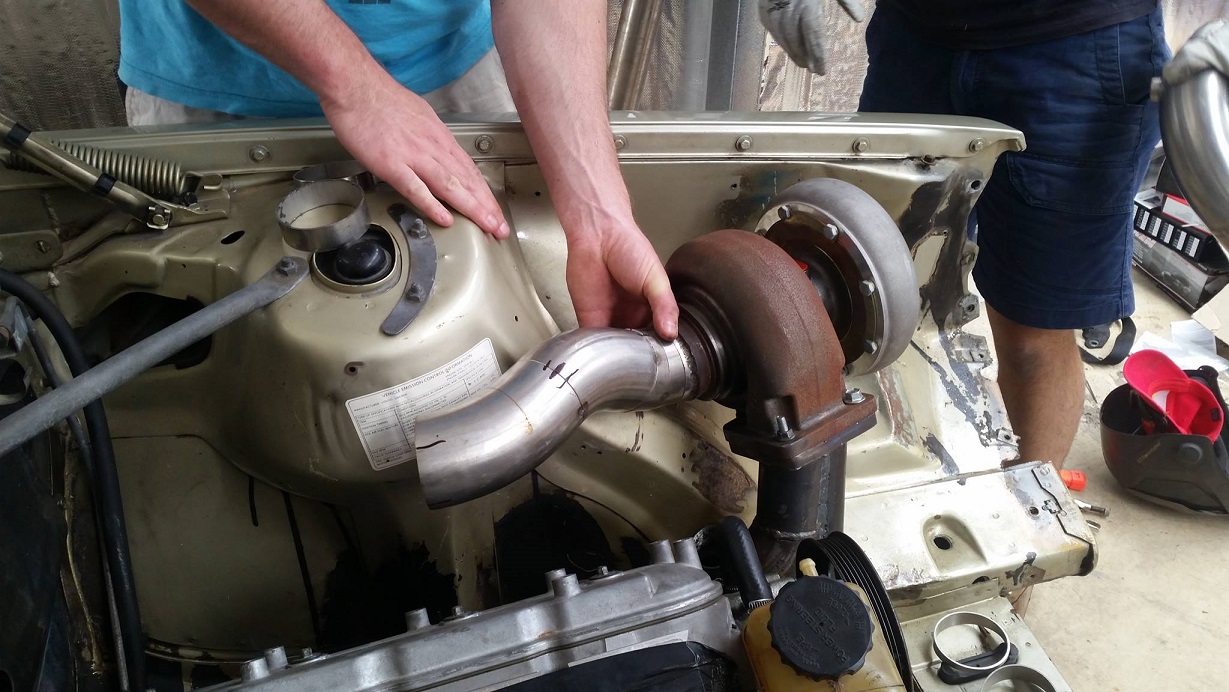

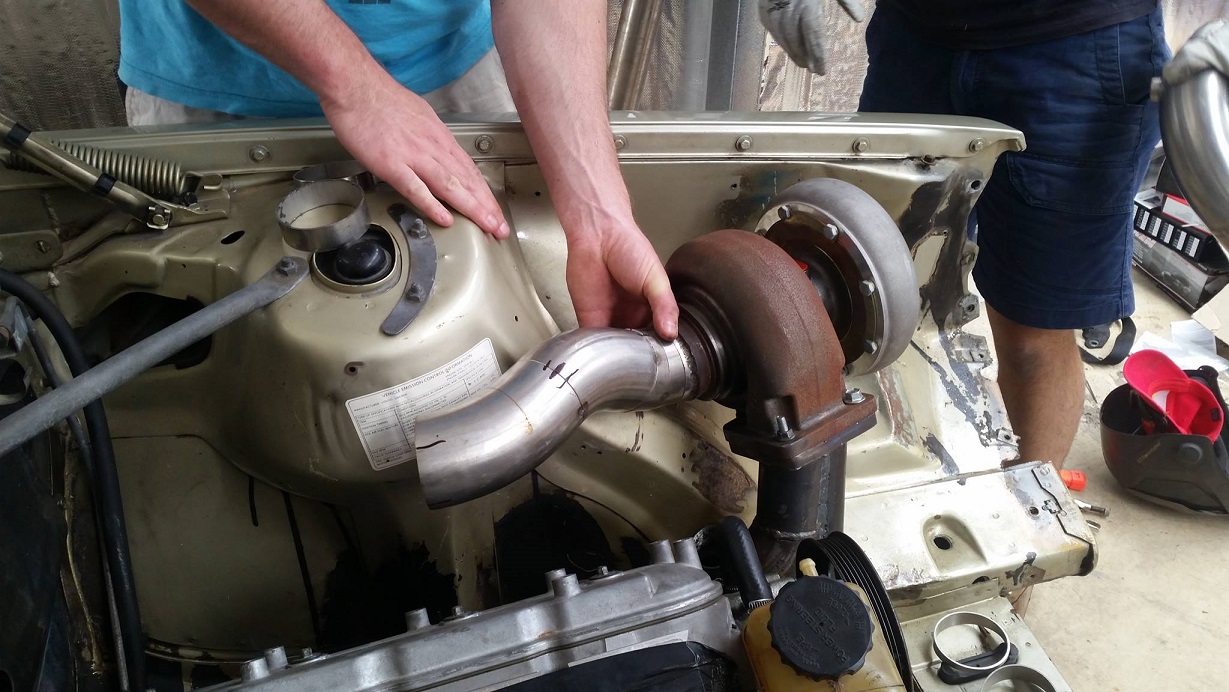

Progress...

Needs a small adjustment on the passenger side. Bit too close to the rail.

Needs a small adjustment on the passenger side. Bit too close to the rail.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

So, a little more progress.

Also bought this...

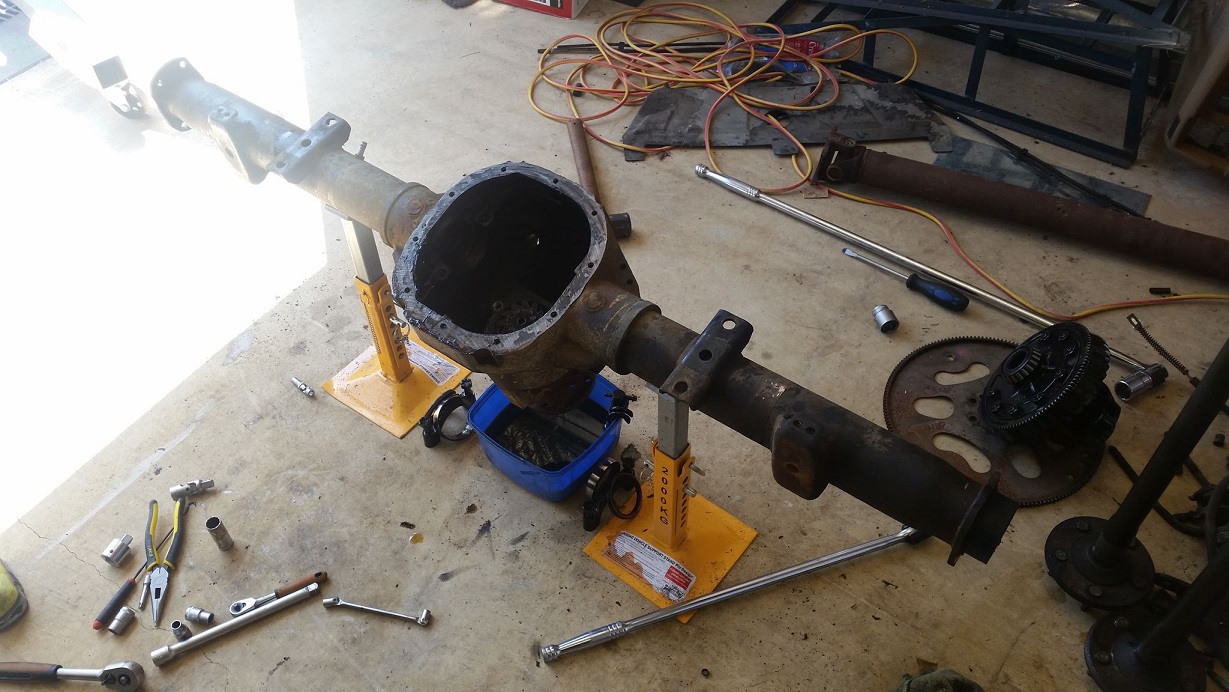

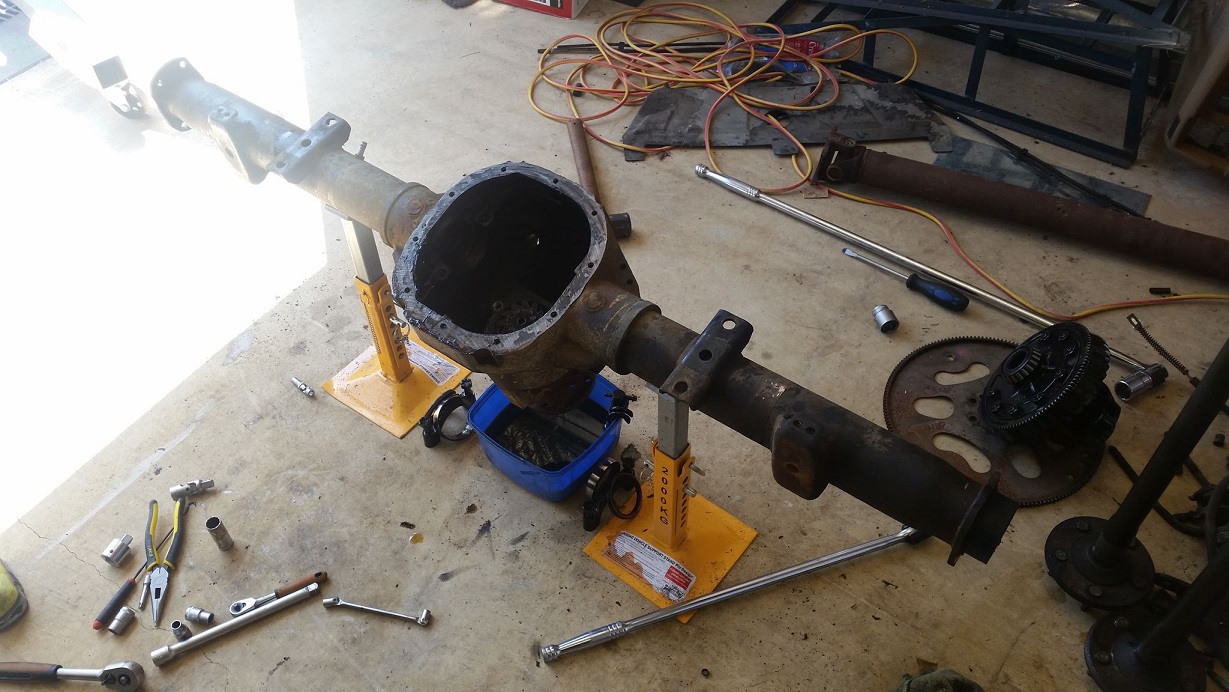

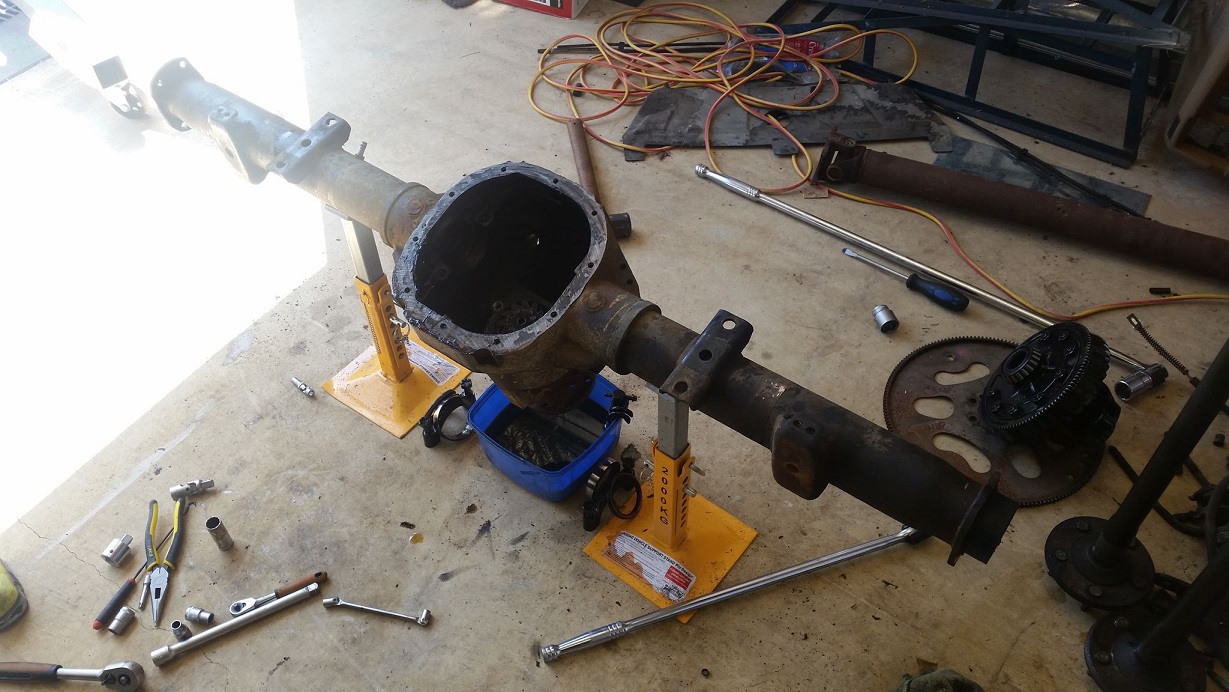

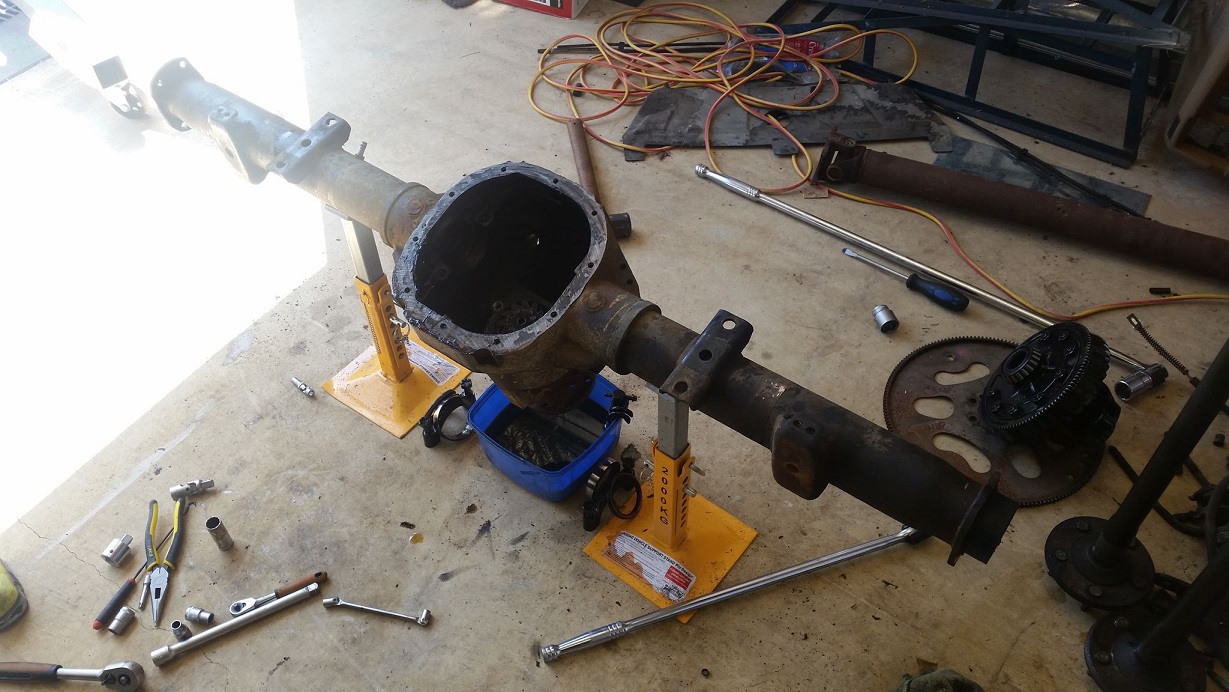

Removing 8.8" diff and some other bits and pieces for franken-lolvo-stein transplant. The rest will go in the bin.

Also bought this...

Removing 8.8" diff and some other bits and pieces for franken-lolvo-stein transplant. The rest will go in the bin.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

whats involved in modifying the diff? Do you then have to run 5x114.3?

No idea. Andy will be guiding me through this. I think we'll just be drilling the hubs to suit Volvo wheels. Will see.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

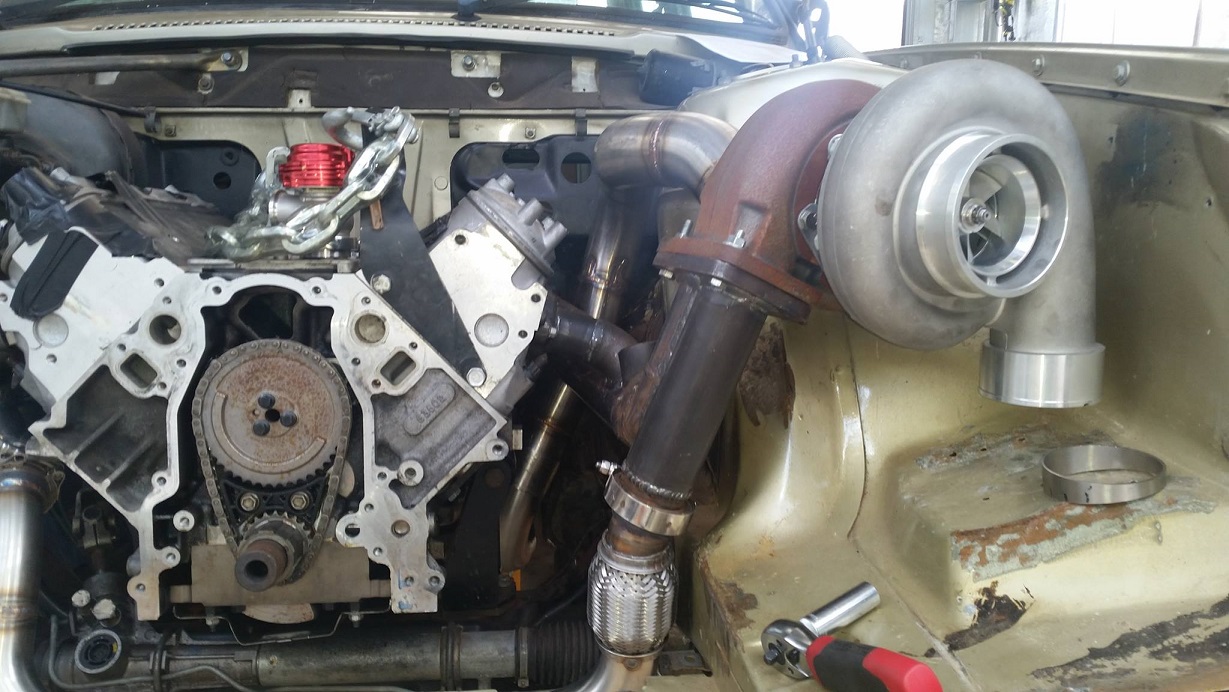

Slow progress still, don't have heaps of time and money to throw at this at the moment

Exhaust clearance, there is heaps! Pretty easy to snake the dump (3" here) around the shock tower and down the rear of the bay. Pretty good clearance everywhere and I haven't even cut the ears off the 4L80e.

Also started working shortening the pan a little bit.

I liked this photo too.

Exhaust clearance, there is heaps! Pretty easy to snake the dump (3" here) around the shock tower and down the rear of the bay. Pretty good clearance everywhere and I haven't even cut the ears off the 4L80e.

Also started working shortening the pan a little bit.

I liked this photo too.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

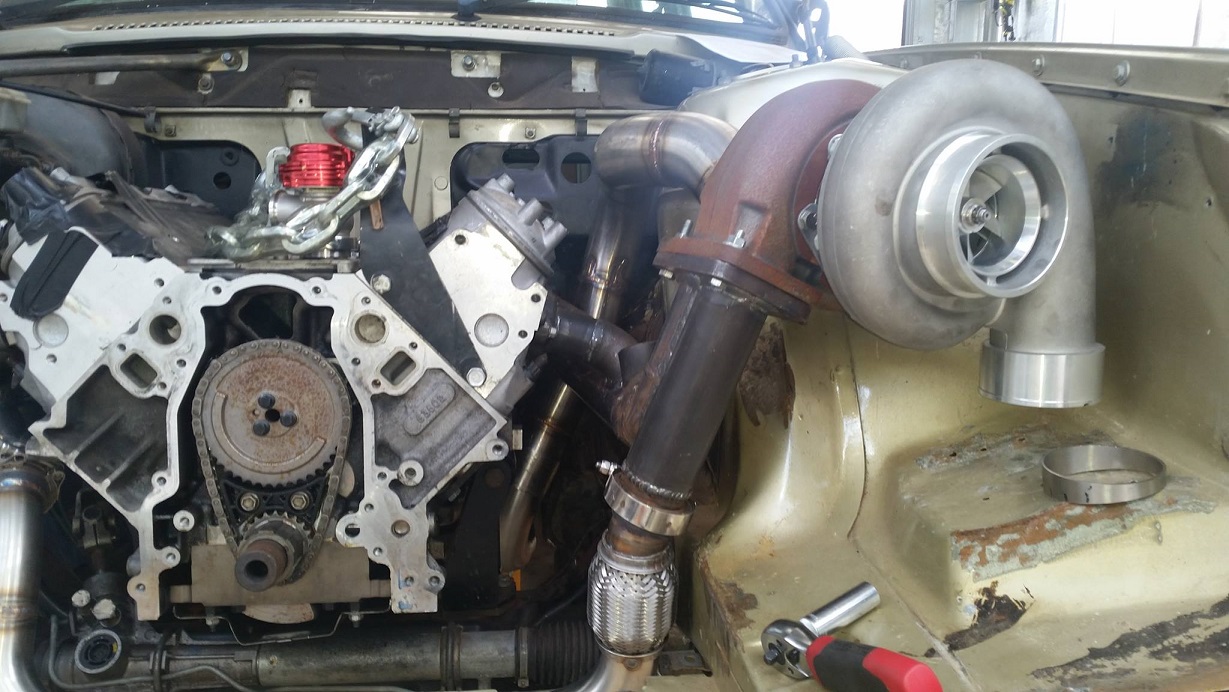

More progress.

Hotside pretty much done, just need to add some flex and wastegates.

Radiator and headlight fits.

And the bonnet closes with about 15mm of clearance from the radiator. Perfect.

Hotside pretty much done, just need to add some flex and wastegates.

Radiator and headlight fits.

And the bonnet closes with about 15mm of clearance from the radiator. Perfect.

AndrewEG

Active member

- Joined

- Jan 21, 2007

- Location

- Aachen, Germany

Looking good Adam. post up some pics of the trans mount and our tunnel mods haha

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

Little update, got this out of the Exploder. Rest is gone to scrap metal heaven.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

Little bit of progress. Made a start on the wiring.

Got the diff out of the Volvo and started work making a jig.

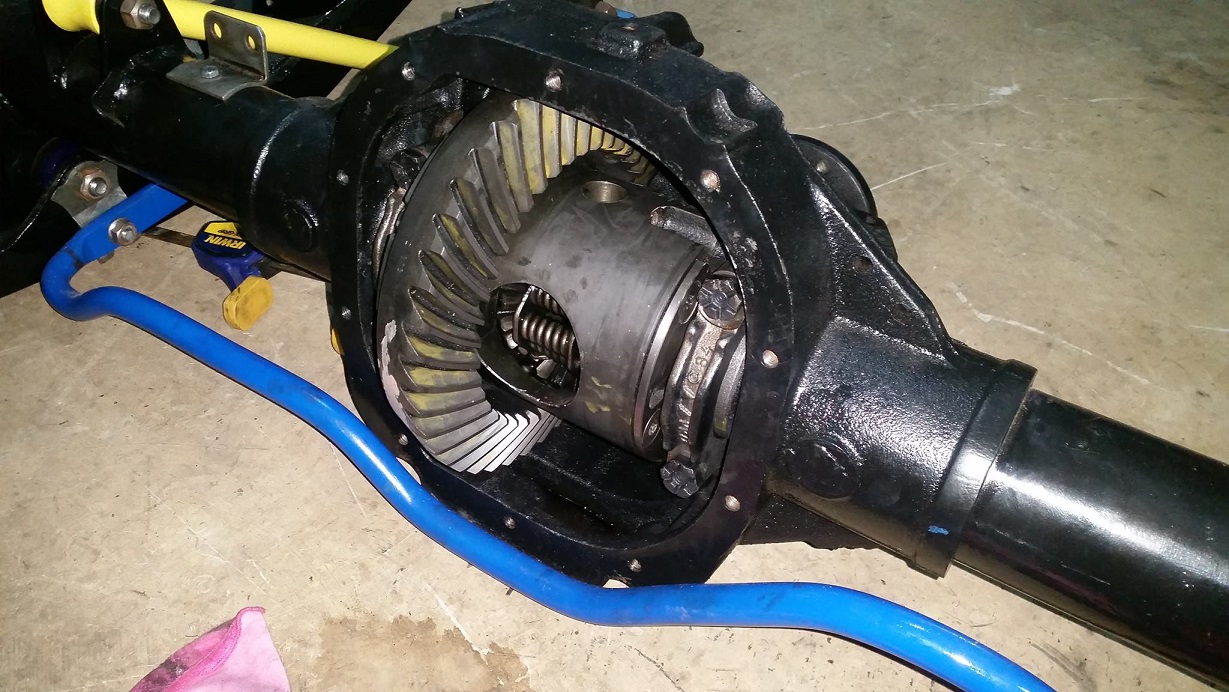

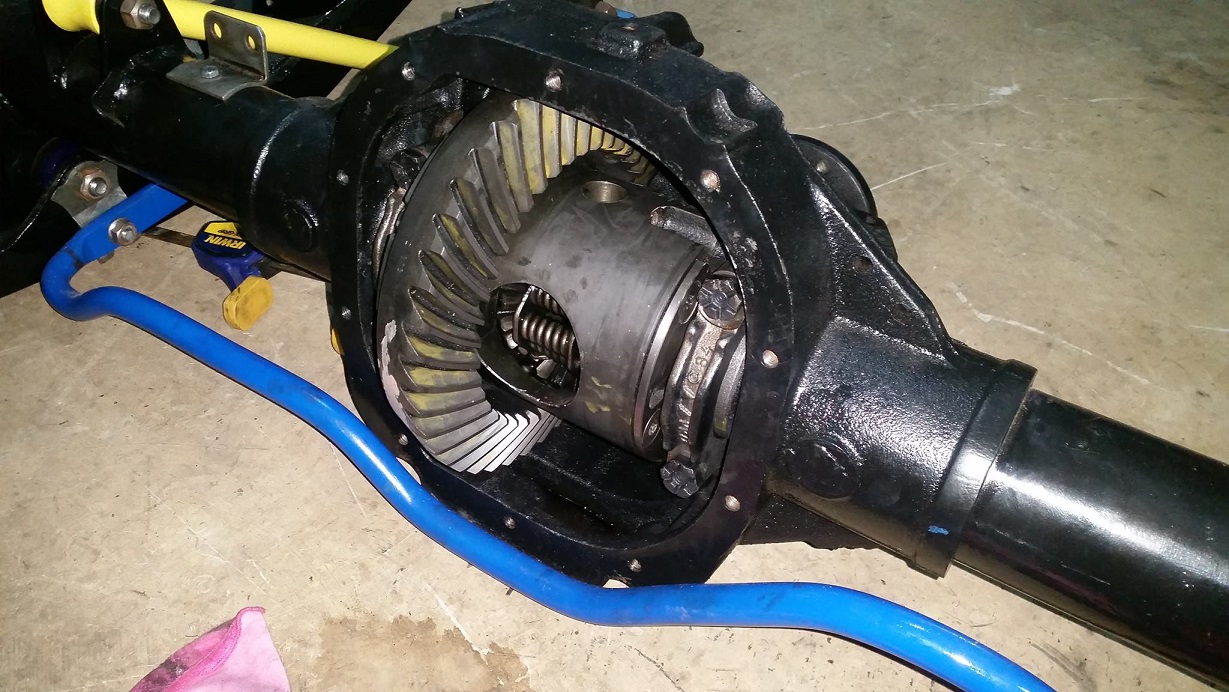

Also got the 8.8 stripped down.

Ran out of stands so just dropped the Volvo down on the fuel tank. She'll be right. Looks good at this height.

Got the diff out of the Volvo and started work making a jig.

Also got the 8.8 stripped down.

Ran out of stands so just dropped the Volvo down on the fuel tank. She'll be right. Looks good at this height.

AndrewEG

Active member

- Joined

- Jan 21, 2007

- Location

- Aachen, Germany

Here's a bit of an update cuunts

Explorer 8.8 diff tube shortened on one side by 74mm and volvo brackets welded on.

A jig was made so that the volvo mounts could be welded in the same position in relation to the tube axis and perpendicular to the pinion axis. Blah blah it all worked perfect.

Tacking the brackets on with the jig attached:

Fillet welding the volvo brackets on with the mig:

[/quote]

[/quote]

Put the diff in the car and it's at the exact factory position. We will still need to have top adjustable reaction rods so that the pinion face is parallel to the trans face. We arn't going to bother welding bump stop plates to the diff as the body mounted bump stops are the same radius of the 8.8 tube.

Plenty of room

You can see that the wastegate port is routed off the cross over tube. Close to the rack but it fits.

This is the current status. The engine will be fired up soon.

In June the final bit of fabrication will be performed to fit the intercooler and piping.

The final bits and pieces to finish off the build will be arriving from summit shortly.

Explorer 8.8 diff tube shortened on one side by 74mm and volvo brackets welded on.

A jig was made so that the volvo mounts could be welded in the same position in relation to the tube axis and perpendicular to the pinion axis. Blah blah it all worked perfect.

Tacking the brackets on with the jig attached:

Fillet welding the volvo brackets on with the mig:

Put the diff in the car and it's at the exact factory position. We will still need to have top adjustable reaction rods so that the pinion face is parallel to the trans face. We arn't going to bother welding bump stop plates to the diff as the body mounted bump stops are the same radius of the 8.8 tube.

Plenty of room

You can see that the wastegate port is routed off the cross over tube. Close to the rack but it fits.

This is the current status. The engine will be fired up soon.

In June the final bit of fabrication will be performed to fit the intercooler and piping.

The final bits and pieces to finish off the build will be arriving from summit shortly.

AndrewEG

Active member

- Joined

- Jan 21, 2007

- Location

- Aachen, Germany

Also this is the modified trans mount.

It fits both TH400 and 4L80e

Here the mount is fitted to the cross member.

It fits both TH400 and 4L80e

Here the mount is fitted to the cross member.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

Progress!

Stripped the 8.8".

Mate made a jig from the old Volvo diff, then transferred the brackets across to the 8.8". Also cut ~70mm out of the tube to make it fit the Volvo (with 2 short-side axles).

Looks good. Short side axle fits perfectly on both sides, but needed to order a pair of new ones due to bearing wear.

Test fit diff. Fits perfectly, will need to put adjusters on the torque rods to correct the input angle.

Removed the bearings with the wrong tool(s) for the job...

Standard vs. replacement LSD.

New suspension bushes and bits ready to go in.

New axles and rebuild kit for the diff. Also Transgo HD-2 kit for the 4L80e.

Getting there...

This is how the engine sits at the moment.

Fan clearance will be tight but the ones I've got should do the job.

Stripped the 8.8".

Mate made a jig from the old Volvo diff, then transferred the brackets across to the 8.8". Also cut ~70mm out of the tube to make it fit the Volvo (with 2 short-side axles).

Looks good. Short side axle fits perfectly on both sides, but needed to order a pair of new ones due to bearing wear.

Test fit diff. Fits perfectly, will need to put adjusters on the torque rods to correct the input angle.

Removed the bearings with the wrong tool(s) for the job...

Standard vs. replacement LSD.

New suspension bushes and bits ready to go in.

New axles and rebuild kit for the diff. Also Transgo HD-2 kit for the 4L80e.

Getting there...

This is how the engine sits at the moment.

Fan clearance will be tight but the ones I've got should do the job.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

Well, made some progress. Got all the bushes out after a lot of swearing, cutting and burning. Got the wire wheel out and cleaned up all the old paint, rust and sound deadening which Volvo spray all over absolutely everything. Gave the parts a fresh coat of rustproof paint, put some new bushes in and started putting some stuff back together.

I cheated a little putting the replacement bushes in but cutting them down the centre with a hacksaw and pressing them in from either side. I can't see any reason this would cause any harm and saved a lot of dicking around.

I cheated a little putting the replacement bushes in but cutting them down the centre with a hacksaw and pressing them in from either side. I can't see any reason this would cause any harm and saved a lot of dicking around.

VQ

Not such a PRVert Anymore

- Joined

- Oct 2, 2005

- Location

- Melbourne, Australia

I like the shed. What size is it? Looks about 8m long? What lighting did you go for?

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

8x6x3m. Got 16x 10w LED floodlights for lighting.

SirNemesis

Member

- Joined

- Oct 30, 2005

- Location

- Geelong, Australia

Update!

Last test-fit of the diff before modifying torque arms.

And assembled with new LSD.

This bearing caused a lot of trouble and needed to be removed by force.

Adjusters done.

Installed.

Will need to elongate the holes in the swaybar so it clears the diff cover. The panhard rod also hits the ring gear, so will need to do some modifications there...

Also picked up some Ford AU Fairmont wheels. They fit perfectly and don't look too out of place on the Volvo.

Cold-side done.

Next up is the brake lines, the radiator fans, shroud and hoses, and then wiring.

Volvo has been pushed outside for the moment. My other car needs a bit of TLC.

Last test-fit of the diff before modifying torque arms.

And assembled with new LSD.

This bearing caused a lot of trouble and needed to be removed by force.

Adjusters done.

Installed.

Will need to elongate the holes in the swaybar so it clears the diff cover. The panhard rod also hits the ring gear, so will need to do some modifications there...

Also picked up some Ford AU Fairmont wheels. They fit perfectly and don't look too out of place on the Volvo.

Cold-side done.

Next up is the brake lines, the radiator fans, shroud and hoses, and then wiring.

Volvo has been pushed outside for the moment. My other car needs a bit of TLC.

ZVOLV

<Master Tech>

- Joined

- Nov 19, 2002

- Location

- California

I have enjoyed the pics.